2026 Best Mechanical Parts Suppliers for Your Needs?

In 2026, the demand for quality mechanical parts suppliers has surged. Industries depend on reliable components to enhance productivity and reduce downtime. According to a recent report by MarketsandMarkets, the global mechanical parts market is projected to reach $800 billion by 2026, reflecting a compound annual growth rate of 5.3%. This growth highlights the crucial role of efficient supply chains.

However, selecting the right mechanical parts suppliers is not straightforward. Many companies face challenges such as inconsistent quality and supply chain disruptions. For instance, a study from Deloitte indicates that nearly 40% of manufacturers encountered supply issues in the past year. This prompts important questions: Are these suppliers meeting today's demands? Are they adaptable to new technologies?

Finding the ideal supplier requires a balance between price and reliability. It’s essential to assess their market reputation and client feedback. Some manufacturers have reported dissatisfaction despite lower costs. Therefore, careful evaluation is needed. Ultimately, the quest for the best mechanical parts suppliers is ongoing.

Factors to Consider When Choosing Mechanical Parts Suppliers

When selecting mechanical parts suppliers, several key factors are critical to ensuring reliable operations. Price hasn't always been the most determining factor. The global mechanical components market is projected to reach $250 billion by 2026, reflecting the increasing demand for high-quality parts. It’s essential to assess the supplier's quality assurance processes. A solid quality control system can minimize defects and improve production efficiency.

Tips: Always ask for certifications. This can validate compliance with industry standards. Request samples to evaluate both product quality and supplier responsiveness.

The geographical location of suppliers should not be overlooked. Local suppliers may offer faster shipping times and lower transportation costs. However, many businesses grapple with the trade-offs between cost and lead times. While overseas suppliers may have lower prices, unexpected delays can be costly. Understanding the balance is crucial.

Tips: Employ multiple suppliers for risk management. This can mitigate the impact of disruptions. Also, develop a clear communication strategy to avoid misunderstandings. By actively monitoring supplier performance, you can adjust your strategies when necessary.

Top Characteristics of Leading Mechanical Parts Suppliers

When selecting mechanical parts suppliers, key characteristics stand out. Reliability is crucial. A dependable supplier meets deadlines consistently. You must ensure they have quality certifications. This helps build trust in their products.

Communication plays a vital role. Suppliers should respond swiftly to inquiries. Transparent communication prevents misunderstandings. However, not all suppliers excel in this area. Sometimes, you may experience delays in responses. This can lead to project setbacks, so keep an open line.

Additionally, evaluate the supplier's technical support. They should offer assistance even after the sale. This support can include installation guidance. Sometimes, suppliers fall short in this aspect. Addressing your technical questions promptly is essential. In such cases, exploring alternative resources may be necessary.

Tip: Always seek testimonials from other customers. Peer reviews provide valuable insights about a supplier's performance. This can save you from potential headaches down the line. Engaging with previous clients might shed light on hidden issues. It helps ensure your choice aligns with your needs.

Overview of the Best Mechanical Parts Suppliers in 2026

When searching for the best mechanical parts suppliers in 2026, several factors come into play. Quality is paramount. A reliable supplier ensures that their components meet high standards. This impact is significant in engineering and manufacturing sectors. If the parts are subpar, the entire project may suffer.

Additionally, suppliers should offer diverse options. Different projects require different materials and specifications. Flexibility in offerings is crucial. Some might not specialize in certain parts. This limits choices and can delay timelines. Clear communication is also vital. Uncertainty leads to mistakes. Suppliers must understand client needs and project goals.

Finally, evaluating supplier reliability is essential. Look for reviews and case studies. A solid reputation is a good indicator. However, not all top-rated suppliers deliver consistently. Some may offer excellent service initially but falter later. Reflecting on these aspects helps improve decision-making. Being methodical and thoughtful can prevent future headaches.

2026 Best Mechanical Parts Suppliers for Your Needs

| Supplier Location | Parts Offered | Average Lead Time | Quality Certification | Customer Satisfaction Rating |

| USA | Bearings, Gears, Fasteners | 2 Weeks | ISO 9001 | 4.8/5 |

| Germany | Hydraulics, Pneumatics | 3 Weeks | DIN EN ISO 9001 | 4.7/5 |

| Japan | Motors, Sensors | 1 Week | JIS Q 9001 | 4.9/5 |

| China | CNC Machining, Castings | 4 Weeks | ISO 13485 | 4.5/5 |

| Italy | Valves, Pumps | 5 Weeks | ISO 9001 | 4.6/5 |

Industry Insights: Trends Influencing Mechanical Parts Supply Chains

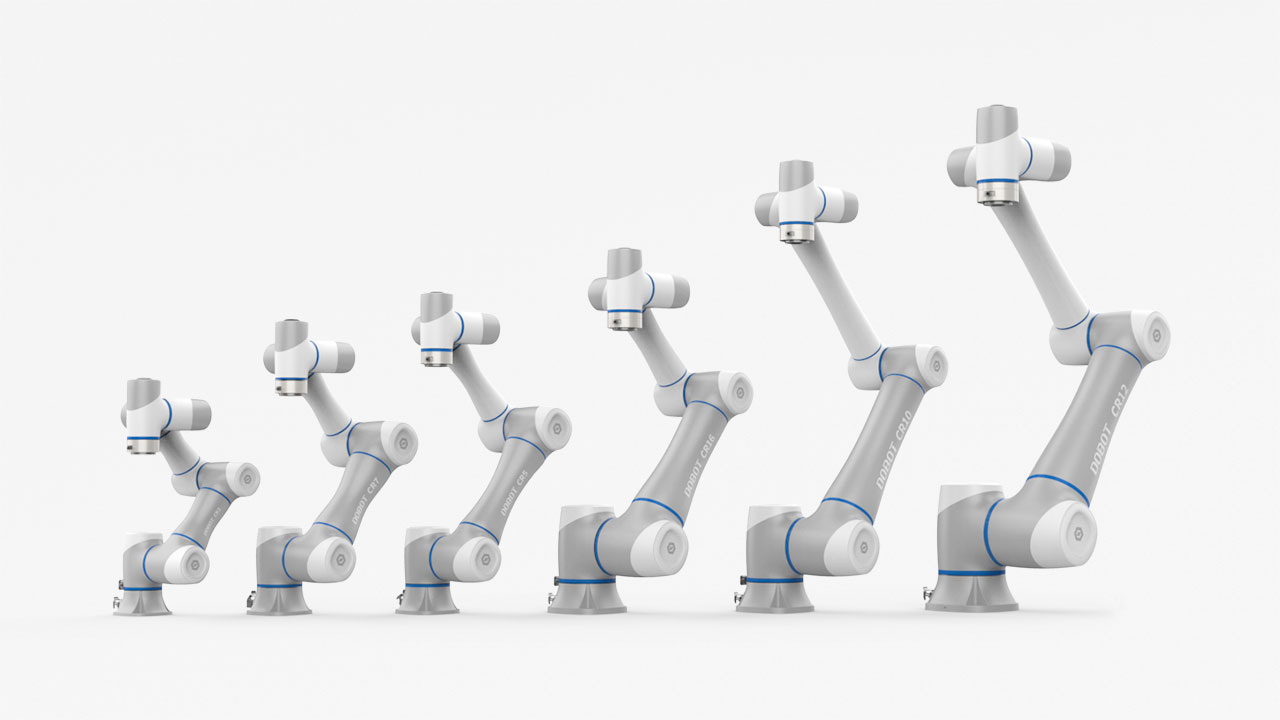

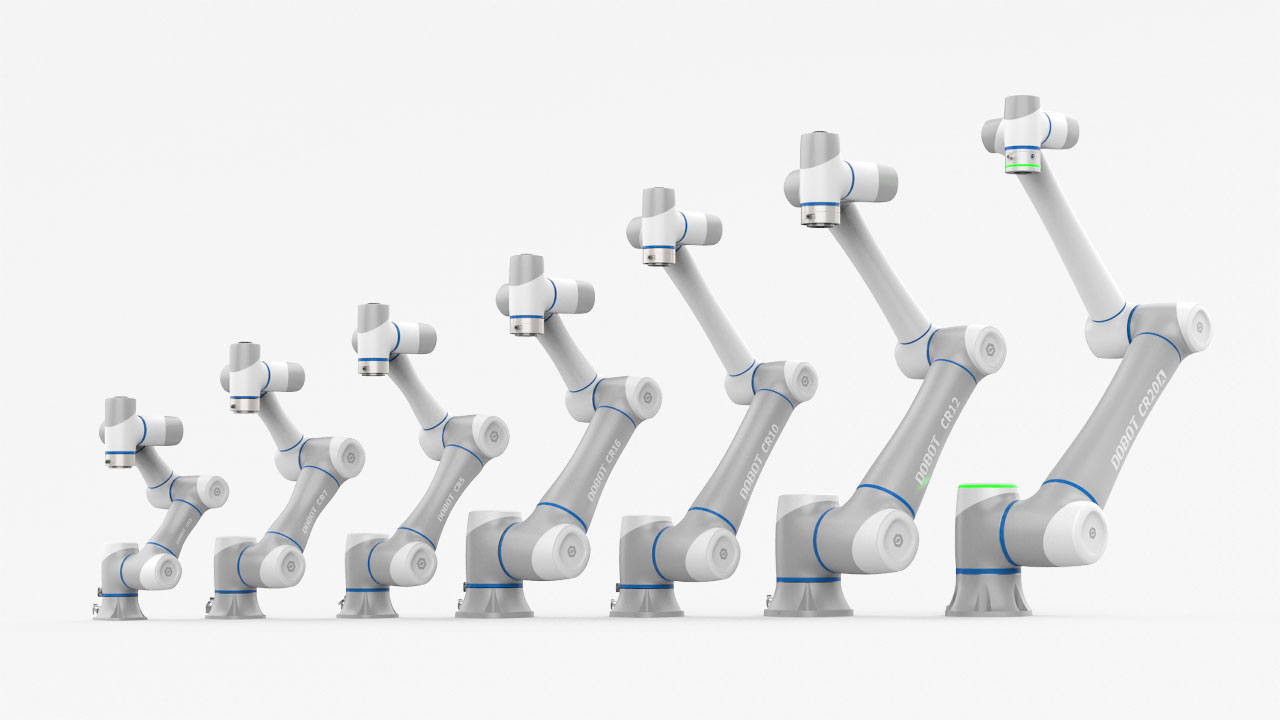

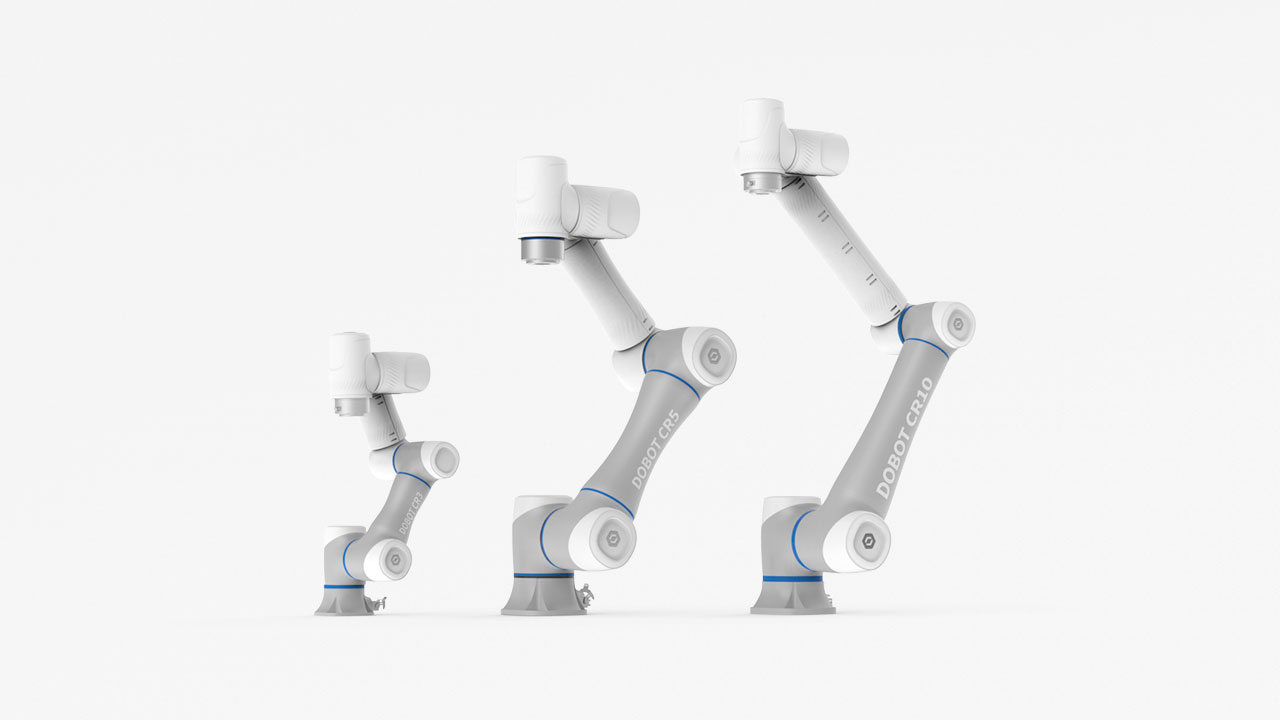

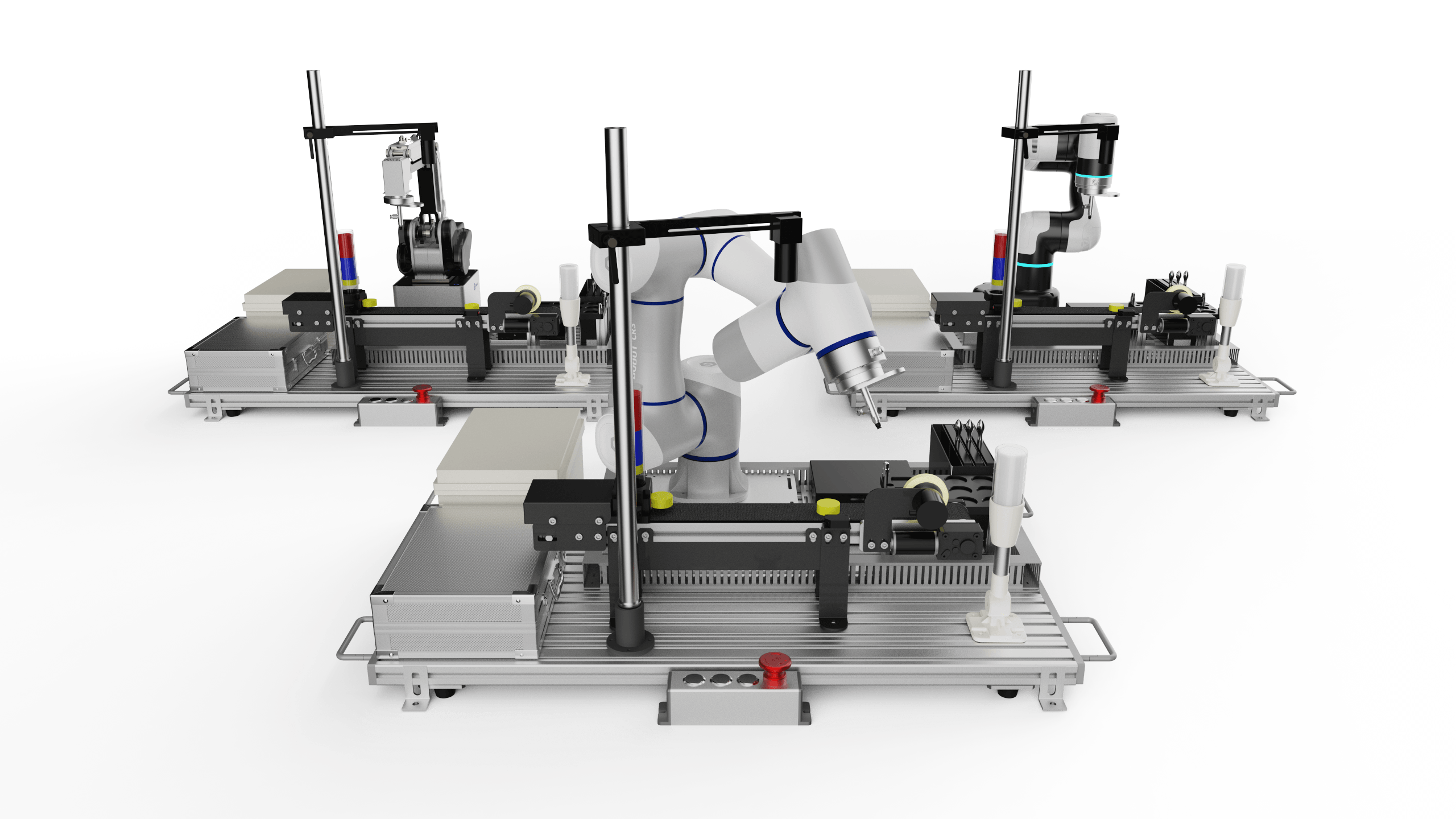

The mechanical parts supply chain is currently influenced by several key trends. One major trend is the increasing demand for automation. Businesses are seeking precise and durable components to enhance operational efficiency. This shift requires suppliers to innovate continuously.

Sustainability is another vital trend. More companies prioritize eco-friendly manufacturing. This means using recycled materials and reducing waste. Suppliers must adapt to these expectations or risk falling behind.

**Tip:** Assess your suppliers' sustainability practices. It can impact your brand's reputation and overall efficiency.

Additionally, supply chain disruptions remain a challenge. These can stem from geopolitical issues or natural disasters. Businesses must prepare for unforeseen delays. Agile suppliers can navigate these complexities more effectively.

**Tip:** Diversify your supplier base. This can safeguard against disruptions.

Investing in strong relationships with suppliers is crucial. Open communication can lead to better solutions. As the landscape changes, staying informed is key. That way, you can make decisions that align with industry trends while addressing your specific needs.

How to Evaluate Mechanical Parts Quality and Supplier Reliability

Evaluating mechanical parts quality and supplier reliability is crucial for production efficiency. According to industry reports, approximately 30% of production delays stem from unreliable suppliers. This highlights the need for rigorous evaluation methods.

One approach is to assess the supplier's history. Look at their track record and customer feedback. Over 70% of manufacturers prioritize supplier reputation when selecting partners. Quality certifications can also serve as indicators. They confirm adherence to standards and can ease concerns about quality.

Product testing is another vital method. Conduct random checks on parts before large-scale implementation. Reports indicate that companies carrying out these tests reduce defect rates by up to 40%. However, not all suppliers will allow such testing. This creates uncertainty and can lead to costly mistakes. Communication with suppliers is essential during this process. Engaging them in discussions about their quality control processes can reveal more than certifications alone.

2026 Best Mechanical Parts Suppliers Analysis