Best Metallurgical Bridge Crane Options for Your Needs?

In the demanding world of metallurgy, the choice of a Metallurgical Bridge Crane can determine efficiency and safety. Recent industry reports indicate that nearly 30% of operational delays are linked to inadequate lifting equipment. This highlights the pressing need for optimal solutions tailored to specific needs.

Metallurgical Bridge Cranes are designed to handle heavy loads and endure extreme conditions. They provide a robust solution for operations requiring precision and reliability. Manufacturers report that using advanced materials and technology has improved performance by over 20%. Yet, many companies struggle to select the right crane for their unique environments.

The market offers various options, but what meets your exact needs? Understanding the capabilities and limitations of each crane type is vital. A mismatch can lead to increased costs and operational inefficiencies. Reflecting on previous choices can guide future decisions. Prioritizing safety and functionality is crucial in this industry.

Types of Metallurgical Bridge Cranes for Different Applications

Metallurgical bridge cranes play a crucial role in various industrial applications. They are designed to handle heavy materials in steel mills, foundries, and metal fabrication shops. These cranes utilize specialized features tailored to their operational needs. For instance, they often come with high-temperature resistances, allowing them to function in environments where molten metals are present.

Different types of metallurgical bridge cranes cater to specific tasks. For heavy lifting tasks, double girder cranes are popular due to their robust structure. According to industry data, these cranes can lift loads exceeding 100 tons. Single girder cranes, while lighter, are suitable for applications requiring moderate lifting capacities. Notably, a report from the Material Handling Industry suggests that investments in these cranes can significantly reduce operating costs by over 30% when efficiently utilized.

Selecting the right type often poses challenges. Users must consider load capacity, operational environment, and required safety features. A single oversight can lead to costly downtimes. Additionally, ongoing maintenance is vital. Failure to inspect the components regularly may lead to accidents or inefficient operations. In the competitive metallurgical sector, the right choice of crane impacts both productivity and safety.

Key Features to Consider When Choosing a Metallurgical Bridge Crane

When selecting a metallurgical bridge crane, several key features should be prioritized. Load capacity is critical. Cranes are often rated for specific weight limits, typically ranging from 5 tons to over 100 tons. It’s important to assess the maximum load frequently handled in your facility. Additionally, the span of the crane can impact operations. A long span can increase coverage and productivity.

Consider the lifting speed, which typically ranges from 10 to 30 meters per minute for metallurgical cranes. Faster speeds can enhance efficiency, but they may also compromise safety. A balance between speed and control is essential.

Tips: Always evaluate the environment. Factors like temperature and dust exposure affect crane performance. Different materials may also require specific designs.

Another feature to think about is the control system. Modern systems offer better precision and ease of use through automation. However, keep in mind that complex controls might need more training. It's a recurring challenge for many facilities.

Reliable data indicates that around 30% of crane accidents occur due to operator error. This highlights the need for comprehensive training and regular maintenance checks. A detailed risk assessment can help identify potential issues.

Safety Standards and Compliance for Metallurgical Bridge Cranes

When it comes to metallurgical bridge cranes, safety standards are crucial. These cranes often operate in high-risk environments. Proper adherence to safety regulations can prevent accidents and ensure the well-being of workers. Compliance with national safety standards is essential. Regular inspections and maintenance should be routine practices.

Tips: Always use protective gear when operating cranes. Conduct safety training for all operators. Ensure load limits are clearly displayed.

In the metallurgical industry, the environment can be harsh. Cranes face extreme temperatures and heavy loads. This increases the likelihood of mechanical failure. Taking time to assess equipment before use can minimize risks. Create a checklist to ensure thorough inspections are done.

Tips: Document any unusual behavior of the crane. Pay attention to strange noises during operation. It might save lives. Regular safety audits can reveal areas needing improvement.

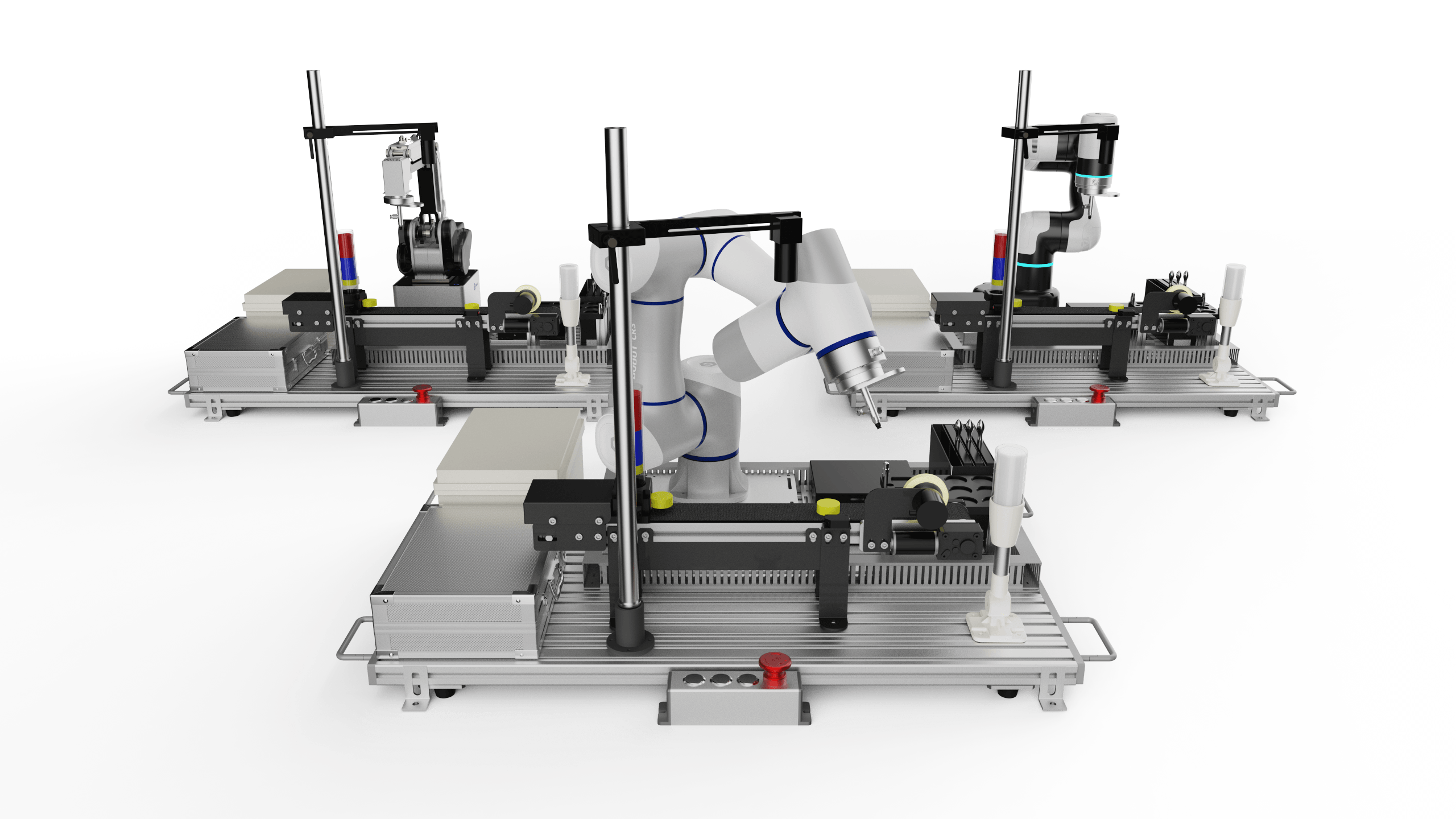

Best Metallurgical Bridge Crane Options for Your Needs

This chart illustrates the different types of metallurgical bridge cranes based on their safety compliance ratings and load capacities. The data reflects inspections and classifications according to current safety standards.

Maintenance and Operational Guidelines for Bridge Cranes

When operating bridge cranes, maintenance is essential for safety and efficiency. Regular inspections help identify issues before they escalate. According to the Crane Manufacturers Association of America, a preventative maintenance program can reduce equipment failure by up to 30%. This statistic highlights the importance of routine checks and servicing.

Operators should also follow operational guidelines closely. Training is crucial. Studies show that 70% of crane accidents stem from operator error. A well-trained operator is less likely to cause accidents and injuries. Effective communication among team members can further enhance operational safety. Use of clear signals and hand gestures can minimize misunderstandings.

Consideration of common wear points is vital. Cables, hooks, and brakes often require more frequent checks. Overlooking these parts can lead to unexpected breakdowns. Many facilities report unplanned downtimes due to neglected maintenance. Taking proactive measures may increase productivity and reduce costly repairs. Striking the right balance between maintenance and operation is key.

Comparative Analysis of Top Metallurgical Bridge Crane Brands

When choosing a metallurgical bridge crane, several brands dominate the market. Each brand has its strengths and weaknesses. According to recent industry reports, approximately 40% of crane users prioritize lifting capacity. This is crucial in metal processing because heavier loads require robust systems.

Durability is another critical factor. Reports indicate that cranes designed for metallurgical applications must withstand extreme conditions. Regular wear and tear can lead to costly downtimes. Many cranes are rated for continuous operation, yet some brands fall short of expected lifespans. A comprehensive analysis reveals that nearly 30% of users experienced performance issues in the first two years.

Safety features play a vital role as well. Data from safety audits show that 25% of accidents are linked to outdated systems lacking modern safety technology. Users often overlook this aspect when making their choice. Investing in advanced safety mechanisms is essential, though some brands provide only basic features. This indicates the need for better evaluations in crane selections. Overall, understanding these comparative aspects aids companies in making informed decisions.