How to Choose the Right Vertical Cargo Lift for Your Business Needs

In the fast-paced world of logistics and warehousing, choosing the right Vertical Cargo Lift is crucial for optimizing operational efficiency and ensuring seamless movement of goods. According to a recent industry analysis by Grand View Research, the vertical lift market is expected to reach $4.7 billion by 2025, with a compound annual growth rate (CAGR) of 5.4%. This growth underscores the increasing demand for vertical lifting solutions that facilitate the safe and efficient transport of various commodities across multiple levels.

As businesses expand and evolve, the need for customized lifting solutions becomes more apparent. Vertical Cargo Lifts offer impressive load capacities and height advantages, making them ideal for warehouses, distribution centers, and manufacturing plants. Data from the Material Handling Industry of America (MHIA) indicates that integrating vertical lifting equipment can lead to a 30% reduction in loading times and a significant decrease in labor costs. Therefore, assessing the unique needs of your business and understanding the potential cost savings and productivity gains associated with Vertical Cargo Lifts can be pivotal in making an informed investment decision.

Factors to Consider When Choosing a Vertical Cargo Lift

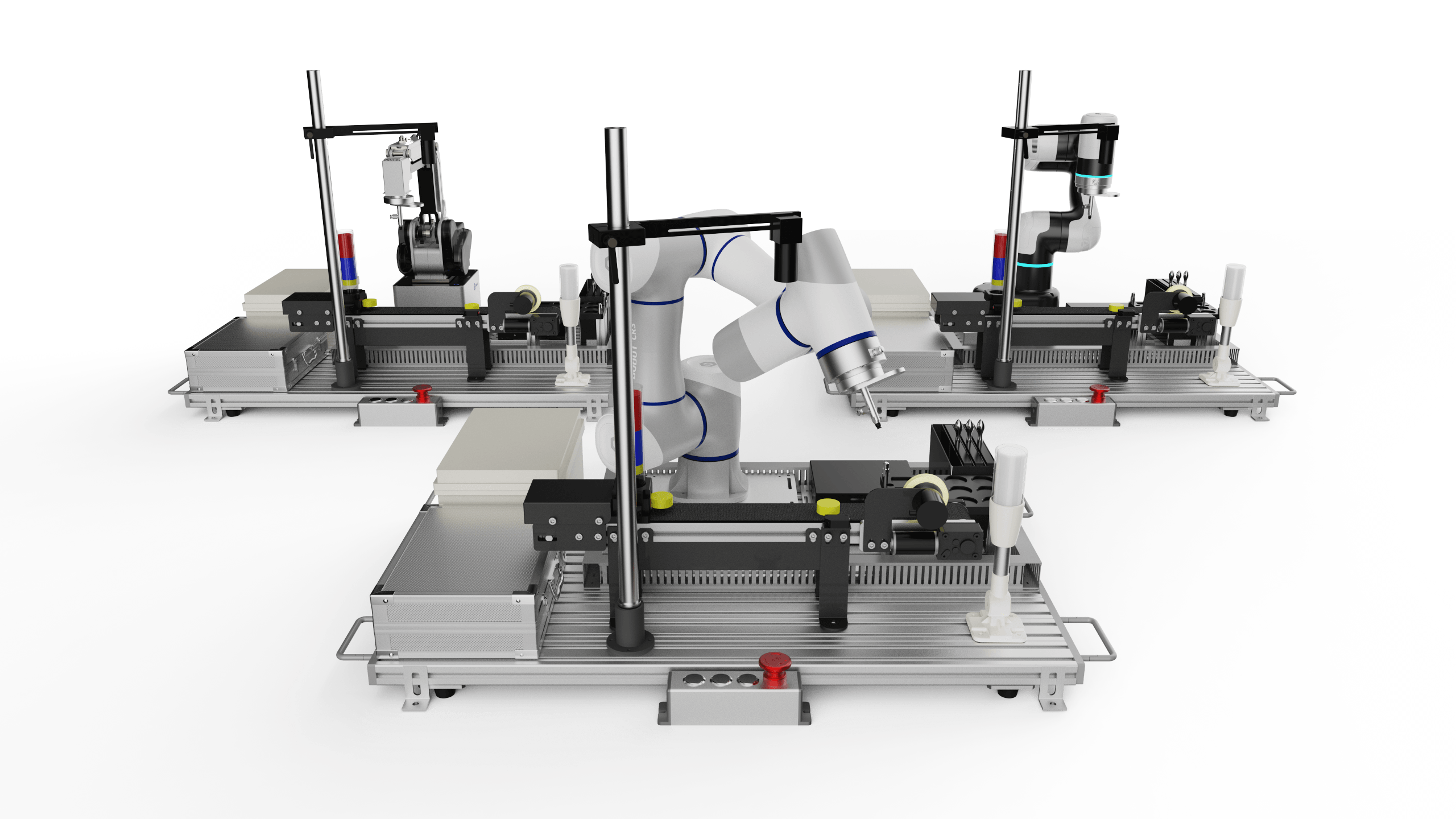

When selecting the right vertical cargo lift for your business, several crucial factors come into play. First and foremost, you must assess the specific operational needs of your facility. Consider the type of cargo you'll be lifting, its weight, and dimensions. This will help determine the lift's capacity requirements. Additionally, the height the lift needs to reach, along with the available space for installation, will influence your decision. It's essential to evaluate your current operational workflow to ensure the lift integrates seamlessly and enhances efficiency.

Another important consideration is the safety features of the vertical cargo lift. Look for models that come equipped with essential safety mechanisms such as emergency stop buttons, safety gates, and overload protection systems. These features contribute to a safer working environment and help prevent accidents. Furthermore, consider the ease of operation and maintenance of the lift. A user-friendly control system and accessible maintenance points can significantly reduce downtime and training requirements for staff, making it pivotal for smooth daily operations.

Factors to Consider When Choosing a Vertical Cargo Lift

Understanding Different Types of Vertical Cargo Lifts

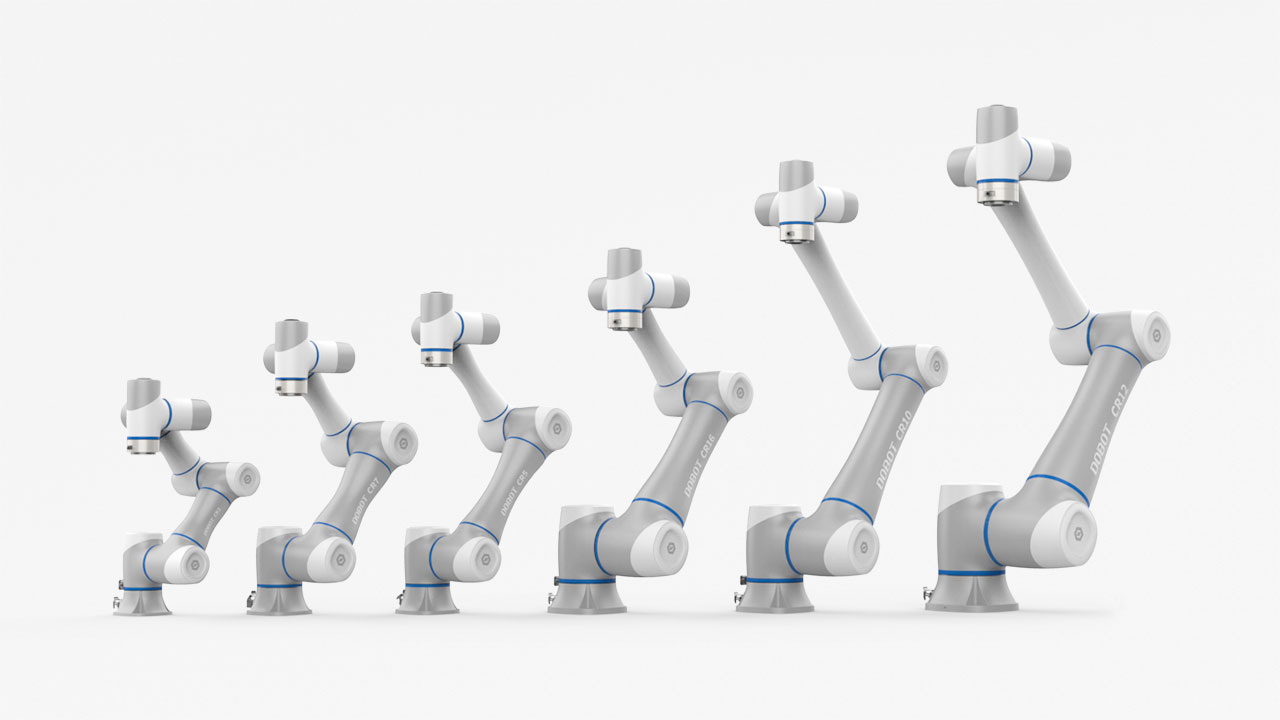

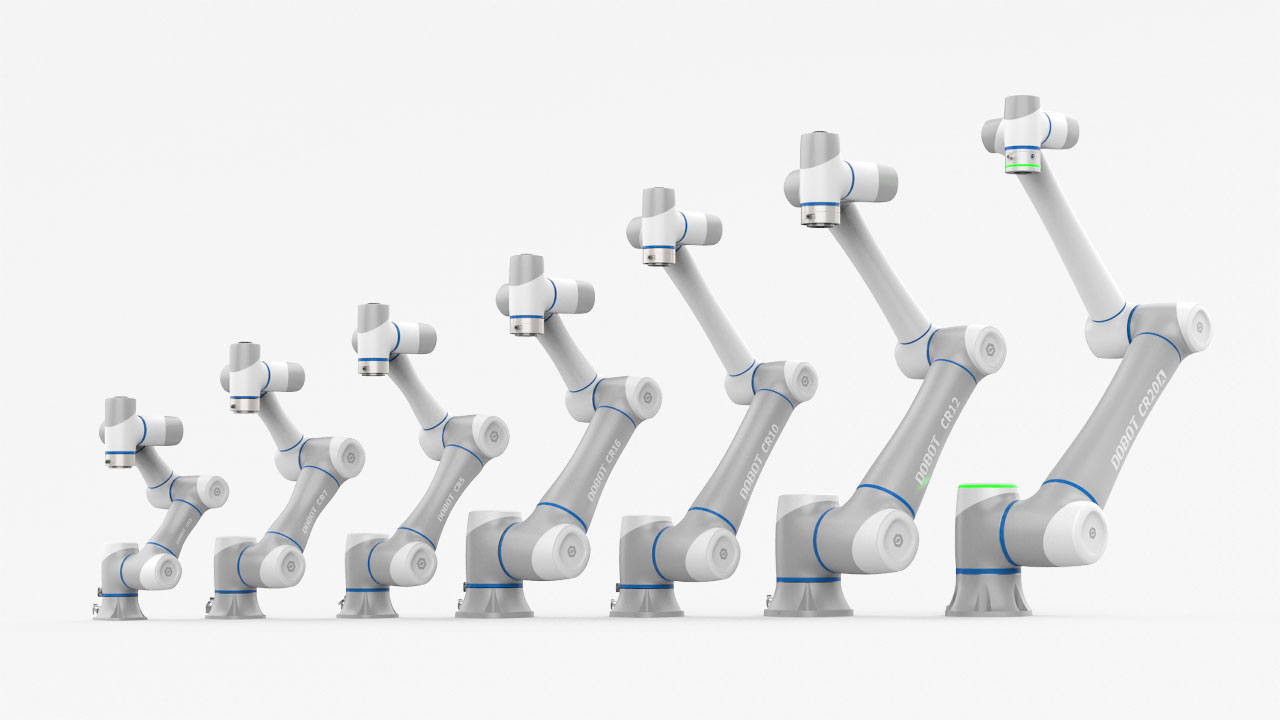

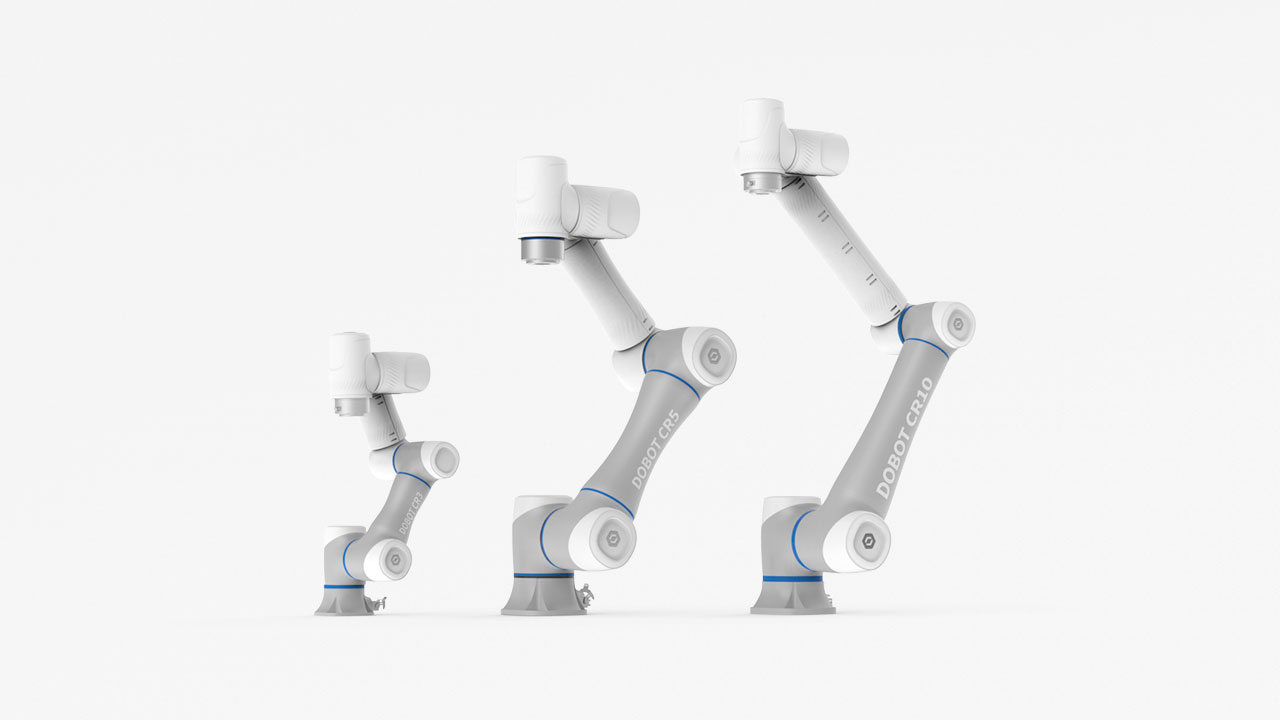

When selecting a vertical cargo lift for your business, it’s crucial to understand the different types available in the market. Vertical cargo lifts come in various designs, each suited for specific applications. For instance, hydraulic lifts are popular in warehouses and factories due to their robust lifting capacity and smooth operation. They utilize hydraulic fluid to lift heavy loads, making them ideal for moving goods between floors in a safe and efficient manner.

Another common type is the mechanical vertical lift, often featuring a chain or screw drive system. These lifts are typically more compact and are engineered for lighter loads, making them suitable for retail environments or small businesses that require efficient vertical transportation of products. Additionally, there are inclined lifts, which can be beneficial in situations where space is limited. They provide the ability to transport goods at an angle, simplifying the logistics of moving cargo without requiring significant overhead clearance. Understanding the specific needs of your business will guide you in choosing the right lift type that enhances operational efficiency while ensuring safety.

How to Choose the Right Vertical Cargo Lift for Your Business Needs - Understanding Different Types of Vertical Cargo Lifts

| Lift Type | Load Capacity (lbs) | Platform Size (in.) | Maximum Lift Height (ft) | Power Source | Ideal Use Case |

| Hydraulic Lift | 2000 | 48 x 48 | 10 | Electric | Warehouses |

| Mechanical Lift | 1500 | 36 x 36 | 8 | Manual/Electric | Retail stores |

| Scissor Lift | 3000 | 60 x 60 | 12 | Electric | Construction Sites |

| Freight Elevator | 5000 | 72 x 72 | 20 | Electric | Industrial Facilities |

| Vertical Platform Lift | 1000 | 36 x 54 | 5 | Electric | Residential Accessibility |

Assessing Your Business's Space and Load Requirements

When choosing the right vertical cargo lift for your business, it's essential to assess your space and load requirements carefully. Start by evaluating the dimensions of your facility. Measure the height of the area where the lift will be installed, as well as the available floor space. This ensures that the lift will fit not only in terms of height but also in the overall footprint, allowing for smooth operation without obstructing other business functions. Additionally, consider any potential height restrictions in your facility, such as overhead beams or ceiling structures.

Next, analyze the types of loads you plan to transport. Different lifts have varying weight capacities, and selecting one that aligns with your business's needs is crucial for both efficiency and safety. Determine the maximum weight of the items you will be lifting and consider their dimensions as well. Regularly transporting large or heavy items will require a more robust lift, while smaller, lighter loads may allow for a less powerful model. Conducting a thorough assessment of your space and load requirements will ultimately guide you in choosing a vertical cargo lift that enhances your operations and meets your specific needs.

Evaluating Safety Features and Compliance Standards

When selecting a vertical cargo lift, one of the paramount considerations is the evaluation of safety features and compliance standards. According to the U.S. Occupational Safety and Health Administration (OSHA), workplace lifts must adhere to specific safety regulations to prevent accidents related to material handling. It is essential to look for lifts that come equipped with features such as emergency stop buttons, overload protection systems, and automatic safety brakes. A report by the National Institute for Occupational Safety and Health (NIOSH) emphasizes that safety devices can significantly reduce the risk of injury by up to 25% in industrial settings.

In addition to mechanical safety features, compliance with industry standards is critical. Organizations such as the American Society of Mechanical Engineers (ASME) provide guidelines for the design and installation of vertical lifts, ensuring they meet required performance and safety criteria. The ASME B20.1 standard outlines essential safety practices for conveyors and related equipment, including vertical lifts, reinforcing the need for thorough inspections and maintenance schedules. Choosing a lift that adheres to these standards not only boosts the safety of the operation but also enhances the overall efficiency of business processes, as reported by industry studies showing a direct correlation between compliance and operational uptime.

Budgeting for Purchase and Maintenance of Cargo Lifts

When considering the purchase of a vertical cargo lift, it’s essential to budget not just for the initial acquisition, but also for ongoing maintenance. A thorough budget allows businesses to accurately assess the total cost of ownership over the lift’s lifespan. This includes factoring in installation costs, periodic maintenance, and potential repairs. By understanding these financial implications upfront, companies can avoid unexpected expenses and ensure that their investment aligns with their operational needs.

Tips: When budgeting for a vertical cargo lift, start by researching different models and their price ranges. Consider the long-term benefits of higher-quality lifts that may come with better warranties and lower maintenance costs over time. Additionally, it's wise to allocate a portion of the budget for routine inspections, as this can prevent costly repairs and prolong the lift's lifespan.

Beyond the purchase price, businesses should also keep in mind the costs associated with training employees on safe usage and maintenance. Proper training can enhance safety, reduce the likelihood of accidents, and improve operational efficiency. A well-maintained cargo lift not only ensures productivity but also minimizes downtime, ultimately saving money in the long run.