2026 How to Choose the Right Stainless Hex Nuts for Your Project?

Choosing the right Stainless Hex Nuts for your project can be challenging. The market is filled with options, making it crucial to understand their unique properties. Industry expert John Smith emphasizes, “Selecting the right nuts impacts the durability of your entire project.” This insight remains vital for engineers and DIY enthusiasts alike.

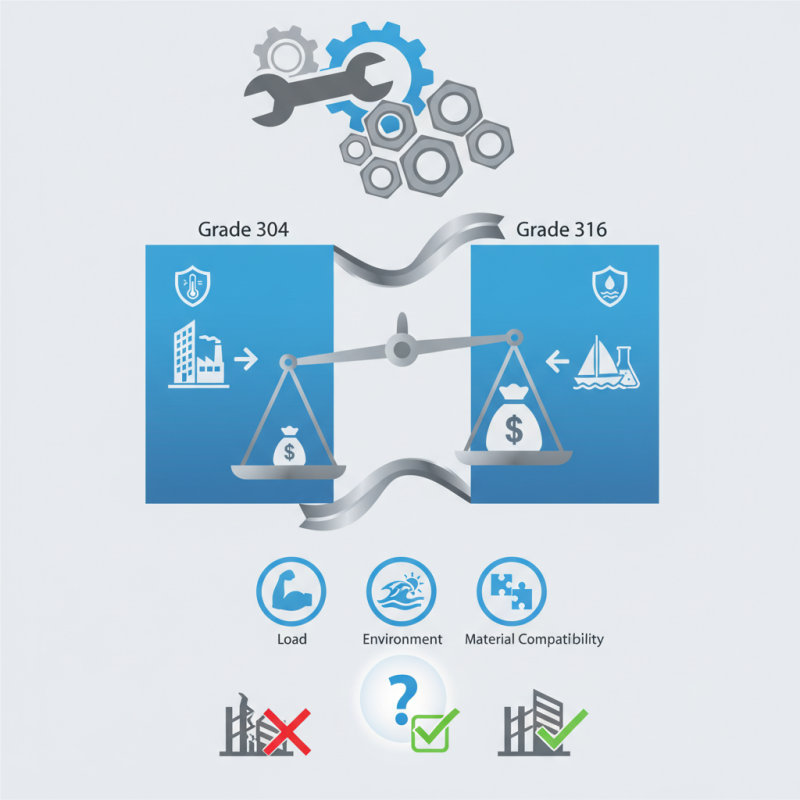

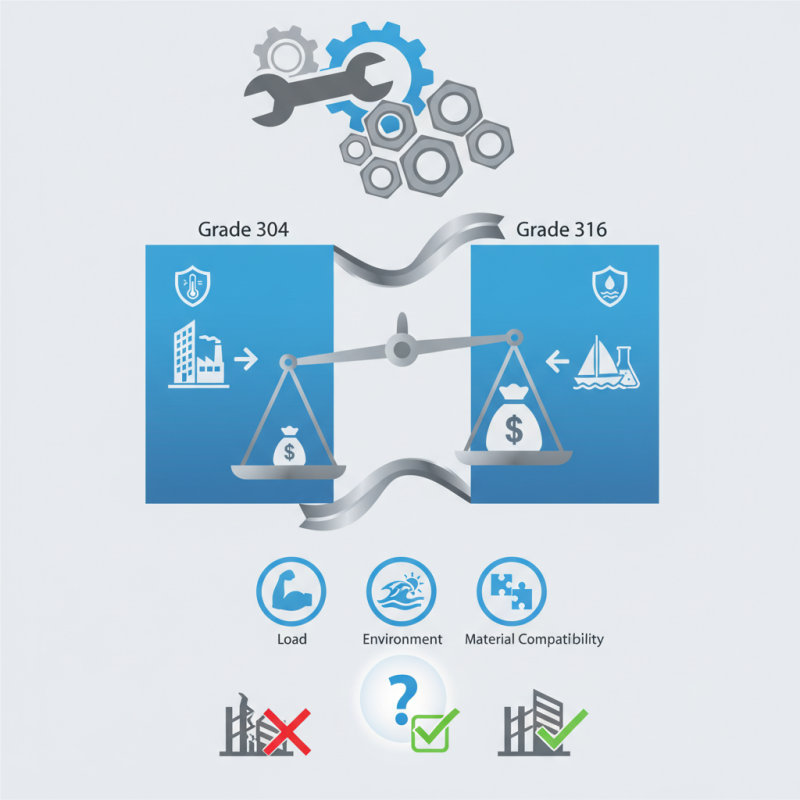

Stainless Hex Nuts come in various sizes and grades. Commonly used grades include 304 and 316, each serving different applications. Knowing the specific requirements of your project is essential. For instance, 316 offers better corrosion resistance and works well in marine environments. However, it may be more costly than 304.

A simple mistake in selection can lead to structural failure. Always consider the load, environment, and material compatibility. While there are many options available, not all are suitable for every application. Reflecting on these factors will lead you to an informed decision.

Understanding the Different Grades of Stainless Steel Hex Nuts

When selecting stainless steel hex nuts, it’s crucial to understand the various grades available. Stainless steel comes in different grades, each with unique properties. Common grades include 304 and 316. Grade 304 is versatile and resistant to corrosion, making it a popular choice. It works well in many environments, especially indoors.

However, if your project is near saltwater or harsh chemicals, consider grade 316. This grade offers better protection against corrosion. It contains molybdenum, enhancing its resistance to pitting. Choosing the right grade involves understanding your environment and the specific requirements of your project.

Yet, many overlook these details and choose based solely on availability or cost. This can lead to poor performance and even failures. Always consider the long-term implications of your choice. Sometimes, spending a little more now can save you hassle later. With the right information, you can make a smarter decision.

Key Factors to Consider When Selecting Stainless Hex Nuts for Projects

Selecting the right stainless hex nuts involves several important factors. Corrosion resistance is a key characteristic. Stainless steel nuts offer durability in various environments. However, not all stainless steel is created equal. You must consider the specific grade that fits your project's needs.

Another crucial factor is the size and thread type. Metric and imperial measurements vary significantly. It’s easy to overlook this detail, but mismatched sizes can lead to failure. Examine your bolts carefully to ensure compatibility. If your project has weight-bearing components, the strength of the nuts matters greatly.

Do not ignore the finish. A polished nut may look appealing, but it might not be practical. Consider the working environment instead. Rough surfaces can provide better grip but may wear out faster. Some may not notice these details until it’s too late. Always reflect on what you need for functionality and longevity.

Common Applications of Stainless Hex Nuts in Various Industries

Stainless hex nuts are widely used across various industries, thanks to their durability and resistance to corrosion. In construction, they hold together structural elements securely. Research shows that nearly 70% of construction projects utilize these nuts in their assemblies. The marine sector also benefits from stainless hex nuts, where exposure to saltwater demands high corrosion resistance.

In the automotive industry, these nuts play a crucial role in engine assembly and bodywork. A recent report indicated that stainless fasteners account for over 20% of total fastener usage in this sector. With the rise of electric vehicles, the demand for reliable nuts is expected to grow.

Tip: Always consider the grade of stainless steel when choosing hex nuts for your application. Not all grades offer the same strength or corrosion resistance. A mismatched selection can lead to project failures.

Some projects may overlook the importance of matching nuts with appropriate bolts. This oversight can weaken the structural integrity of assemblies. In the aerospace sector, rigorous standards are vital for safety. The right choice of stainless hex nuts can elevate performance and ensure compliance with regulations.

Best Practices for Sizing and Compatibility of Hex Nuts with Bolts

Choosing the right stainless hex nuts is critical for project success. Sizing and compatibility with bolts are two key factors to consider. A recent industry report highlights that approximately 30% of project failures stem from improper nut and bolt pairing. Therefore, precise measurements are essential.

When selecting hex nuts, ensure that the thread pitch matches the corresponding bolts. Common sizes include coarse and fine threads, which influence the strength and fit. For example, a fine thread can resist vibration better, while coarse threads offer easier assembly. Use calipers for accurate measurements. Any discrepancies can lead to significant issues, like stripped threads or loose fittings.

Additionally, material compatibility can't be overlooked. Stainless steel is resistant to corrosion, but factors like grade and finish matter. The 304 grade is versatile for many applications. However, in aggressive environments, the 316 grade performs better. An industry survey shows that about 40% of users choose the wrong grade, impacting durability and longevity. Ensure to review project requirements and environmental conditions for optimal selections.

2026 Stainless Hex Nuts Compatibility Chart

This chart illustrates the compatibility of different sizes of stainless hex nuts with corresponding bolt sizes. Choosing the right hex nut is crucial for ensuring a secure fit and reliable performance in your projects.

Tips for Ensuring Quality and Durability in Stainless Hex Nuts Selection

When selecting stainless hex nuts for your project, quality and durability are key. The choice can greatly impact your work. Proper selection ensures the integrity of your assembly. Start by examining the material grade. Not all stainless steel is the same. For demanding environments, consider higher grade options. This simple step can prevent future failures.

Tips for ensuring quality include checking the nut's finish. A smooth, uniform finish suggests better manufacturing practices. Look for certification marks that indicate compliance with industry standards. These details matter. They can be the difference between short-term use and long-lasting performance.

Pay close attention to dimensions. A mismatch can cause significant issues. Measure both internal and external sizes accurately. Also, ensure that the threads are uniform and well-defined. Sometimes, these tiny imperfections are easy to overlook. Reflect on your choices and their potential impact on your project.