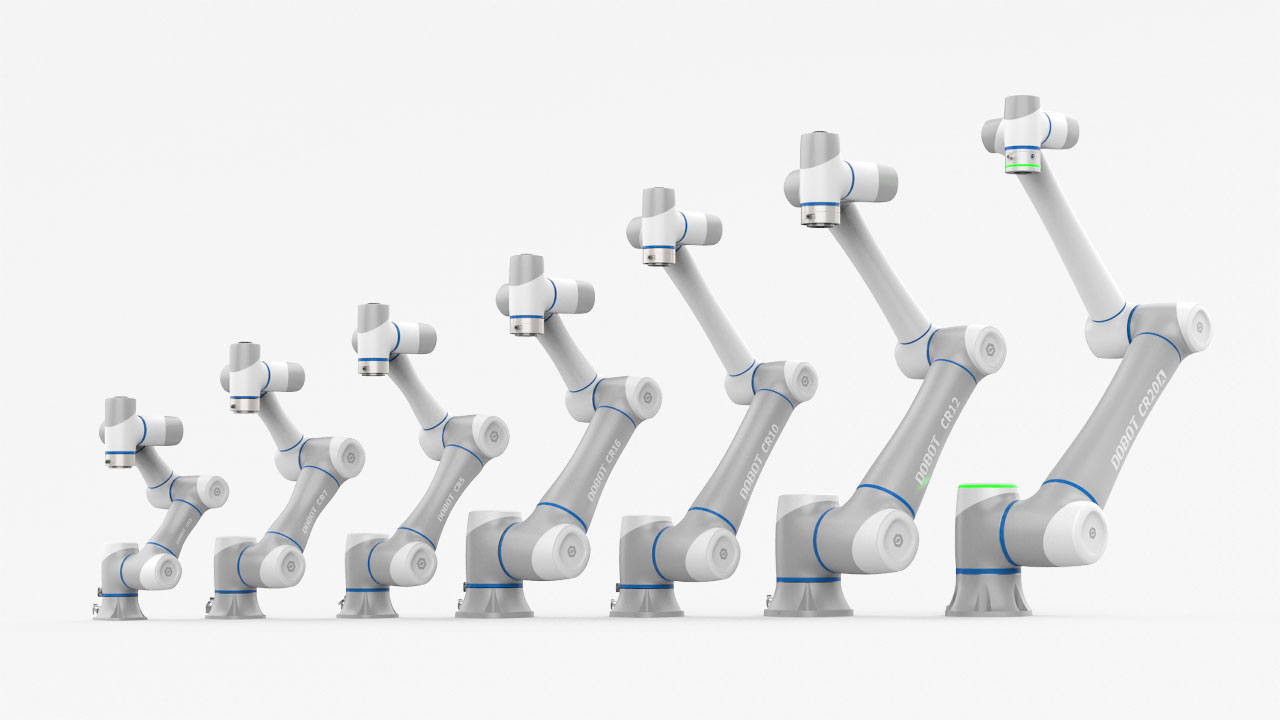

The Complete Guide to Choosing the Best Manipulator Arms for Your Business

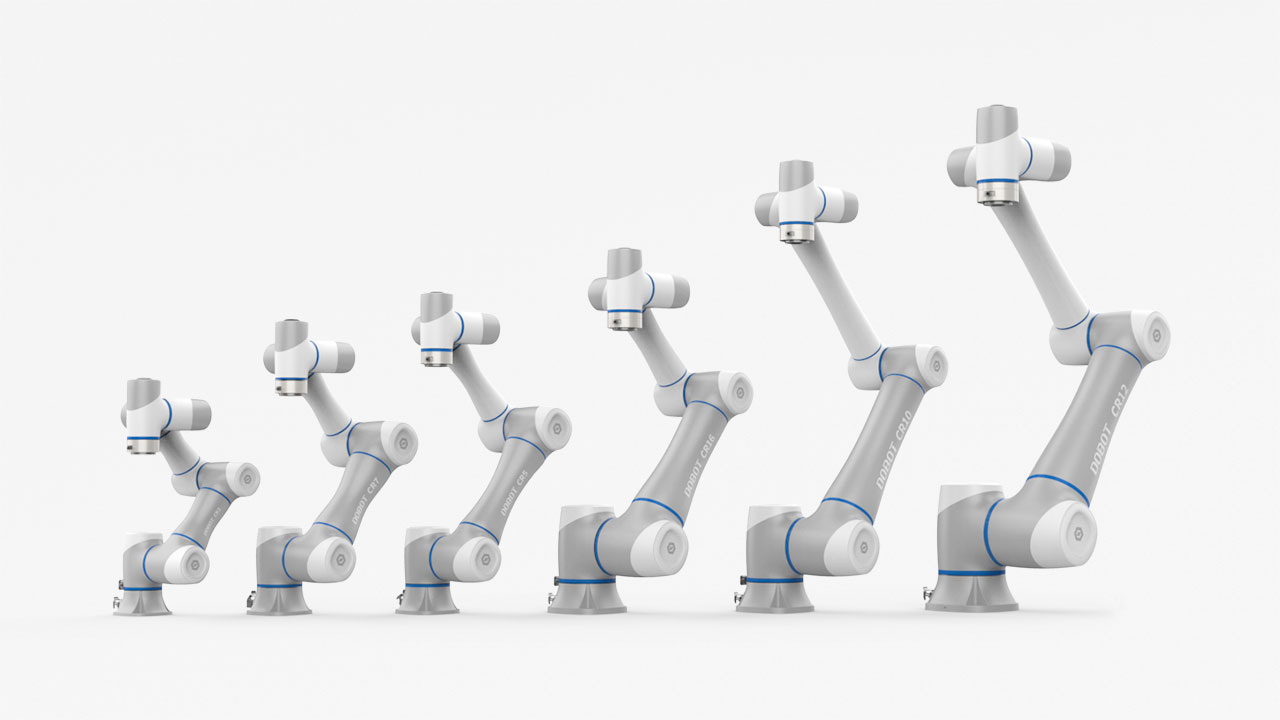

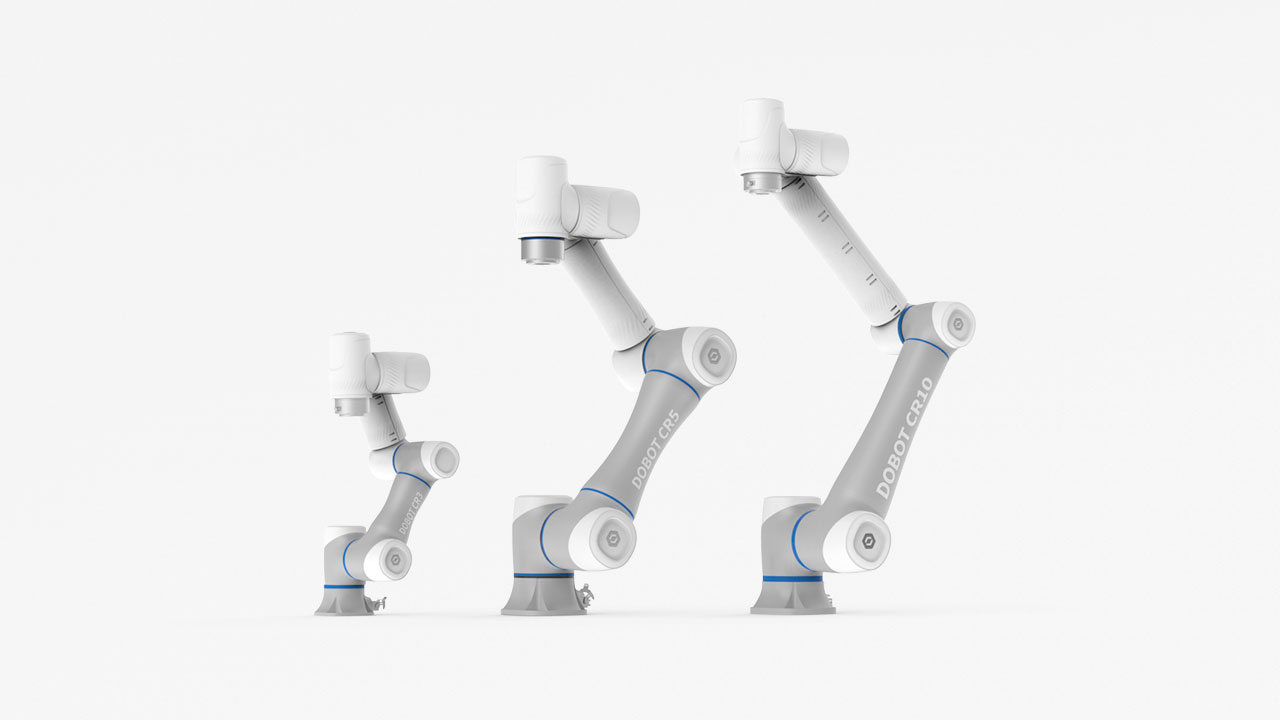

In today's fast-paced manufacturing environment, selecting the right tools for operational excellence is crucial. One such tool, the Manipulator Arms, plays a pivotal role in enhancing productivity and ensuring precision in various industrial tasks. However, the process of choosing the best Manipulator Arms for your business can be fraught with challenges.

From understanding the different types of manipulator arms available to navigating industry production standards, businesses often face significant hurdles that can impact performance and bottom-line results.

This comprehensive guide aims to illuminate the common problems associated with different types of manipulator arms and provide actionable insights to help you make informed decisions.

Whether you are new to the world of manipulator arms or looking to upgrade your existing equipment, our guide will equip you with the knowledge needed to choose the best fitting solution for your specific needs.

From understanding the different types of manipulator arms available to navigating industry production standards, businesses often face significant hurdles that can impact performance and bottom-line results.

This comprehensive guide aims to illuminate the common problems associated with different types of manipulator arms and provide actionable insights to help you make informed decisions.

Whether you are new to the world of manipulator arms or looking to upgrade your existing equipment, our guide will equip you with the knowledge needed to choose the best fitting solution for your specific needs.

Benefits of Strong After-Sales Service for Manipulator Arms

When investing in manipulator arms for your business, the significance of strong after-sales service cannot be overstated. According to a report by MarketsandMarkets, companies with robust after-sales support can improve customer retention rates by up to 20%. This is particularly crucial in industries relying heavily on automated systems where downtime can lead to significant financial losses. Comprehensive technical support ensures that businesses can resolve issues rapidly, minimizing interruptions and enhancing productivity.

Moreover, 77% of B2B buyers report that they would recommend a supplier based more on service and support than on the product itself, as highlighted in the State of B2B Procurement report. For manipulator arms, which are essential in streamlining workflows and enhancing efficiency, the presence of strong after-sales service directly impacts user satisfaction and operational continuity.

Companies that prioritize after-sales support not only foster long-term relationships with clients but also cultivate a reputation for reliability in a competitive market. Investing in manipulator arms from providers known for excellent after-sales service is therefore a strategic choice that can lead to better overall performance and profitability.

Understanding Repair Costs and Their Impact on Business Operations

When selecting manipulator arms for your business, it’s crucial to consider how

repair costs will affect your overall operations.

In various industries, including helicopter maintenance, repair, and overhaul (MRO),

understanding these expenses contributes significantly to managing budgets effectively.

High repair costs can lead to increased downtime, impacting productivity and customer satisfaction.

Tips:

Always evaluate the warranty and service agreements of manipulator arms.

Investing in equipment with robust support can mitigate long-term repair costs.

Regular maintenance can also enhance the longevity of your equipment, thereby reducing the likelihood of unexpected repairs.

Additionally, consider the technological advancements

associated with manipulator arms that can simplify repairs and lower costs. Newer models may

offer user-friendly interfaces and diagnostics that allow for quicker troubleshooting.

Tips:

Conduct thorough research on the latest manipulator arm technologies. Engaging with suppliers

who offer training and resources can help your team efficiently

handle any repairs, ultimately ensuring minimal disruption to your business operations.

Evaluating Warranty Options: What Businesses Should Know

When selecting manipulator arms for your business, evaluating warranty options is a crucial step that can safeguard your investment. A robust warranty not only reflects the manufacturer's confidence in their product but also provides peace of mind by protecting against defects and performance issues.

Businesses should closely examine the length and terms of the warranty, as well as what specifically is covered. For instance, does the warranty include parts, labor, and on-site service? Understanding these details can help businesses avoid unexpected costs in the future.

Additionally, consider the reputation of the manufacturer regarding warranty support. A company that is known for responsive customer service and efficient claim processing can make a significant difference in minimizing downtime if an issue arises.

It is also beneficial to inquire about the experiences of other customers who have claimed warranties, as this can provide insights into the reliability of the warranty support. Ultimately, a well-structured warranty agreement can be an invaluable component of your overall decision-making process,

ensuring that you choose the right manipulator arms that not only meet your operational needs but also come with essential protection for your investment.

Best Practices for Minimizing Maintenance Expenses on Manipulator Arms

Minimizing maintenance expenses for manipulator arms is crucial for businesses operating in assembly lines and material handling. According to a report from the

International Federation of Robotics, regular maintenance can reduce unexpected equipment failures by as much as 30%. By implementing a proactive maintenance schedule, companies can not only extend the lifespan of their

manipulator arms but also enhance their performance and operational efficiency.

One of the best practices for minimizing these expenses is investing in high-quality components that require less frequent replacements. A study published by the

Machinery Maintenance Institute indicates that businesses using premium parts experience a 25% reduction in annual maintenance costs compared to those that opt for lower-quality alternatives.

Additionally, adopting predictive maintenance technologies, which utilize data analytics to anticipate failures before they occur, can save companies up to 20% on maintenance costs. By focusing on these strategies, organizations can ensure their manipulator arms remain reliable, leading to improved productivity and reduced downtime.

Choosing Suppliers with Robust Customer Support for Your Manipulator Needs

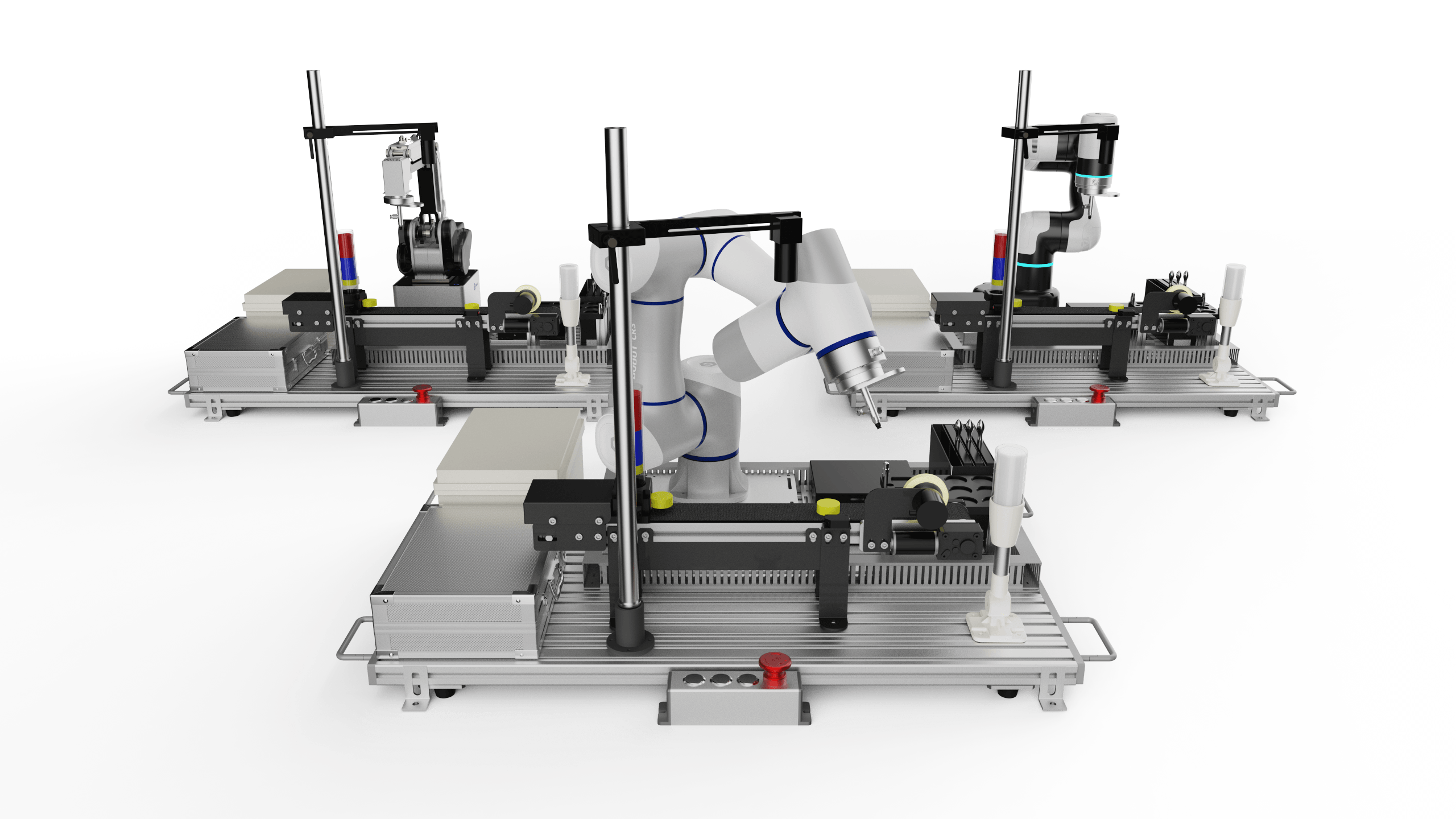

When selecting manipulator arms for your business, it is crucial to choose suppliers that offer robust customer support. The complexity of these systems often necessitates ongoing communication with the supplier, especially during installation, operation, and maintenance phases. Reliable customer support can ensure that any issues are resolved quickly, minimizing downtime and increasing productivity. Look for suppliers who provide dedicated support teams that can assist you in real time, whether through phone, email, or live chat.

In addition to immediate assistance, a good customer support structure should include extensive resources such as user manuals, FAQs, and how-to videos. These resources empower your team to troubleshoot minor issues independently, streamlining your operations. Furthermore, exploring online reviews and testimonials can give you insight into a supplier's reliability and responsiveness. By prioritizing suppliers with strong customer support, you ensure a smoother integration of manipulator arms into your business, allowing you to focus on enhancing efficiency and achieving your organizational goals.

From understanding the different types of manipulator arms available to navigating industry production standards, businesses often face significant hurdles that can impact performance and bottom-line results.

This comprehensive guide aims to illuminate the common problems associated with different types of manipulator arms and provide actionable insights to help you make informed decisions.

Whether you are new to the world of manipulator arms or looking to

From understanding the different types of manipulator arms available to navigating industry production standards, businesses often face significant hurdles that can impact performance and bottom-line results.

This comprehensive guide aims to illuminate the common problems associated with different types of manipulator arms and provide actionable insights to help you make informed decisions.

Whether you are new to the world of manipulator arms or looking to