How to Enhance Building Efficiency with Construction Robots in the Modern Industry

In recent years, the construction industry has witnessed a significant transformation, driven by the adoption of innovative technologies aimed at enhancing building efficiency. Among these advancements, Construction Robots have emerged as a pivotal element in streamlining operations, reducing labor costs, and minimizing human error.

According to the "World Robotics Report 2021", the global market for construction automation is projected to reach $1.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 14.5%. Furthermore, McKinsey & Company reports that integrating robotics into construction processes can lead to a productivity increase of up to 30%. As the industry grapples with labor shortages and the demand for faster project completion, leveraging Construction Robots proves essential for companies aiming to remain competitive in a rapidly evolving market.

This article explores effective strategies to incorporate these technologies, ultimately enhancing efficiency and productivity in modern construction practices.

According to the "World Robotics Report 2021", the global market for construction automation is projected to reach $1.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 14.5%. Furthermore, McKinsey & Company reports that integrating robotics into construction processes can lead to a productivity increase of up to 30%. As the industry grapples with labor shortages and the demand for faster project completion, leveraging Construction Robots proves essential for companies aiming to remain competitive in a rapidly evolving market.

This article explores effective strategies to incorporate these technologies, ultimately enhancing efficiency and productivity in modern construction practices.

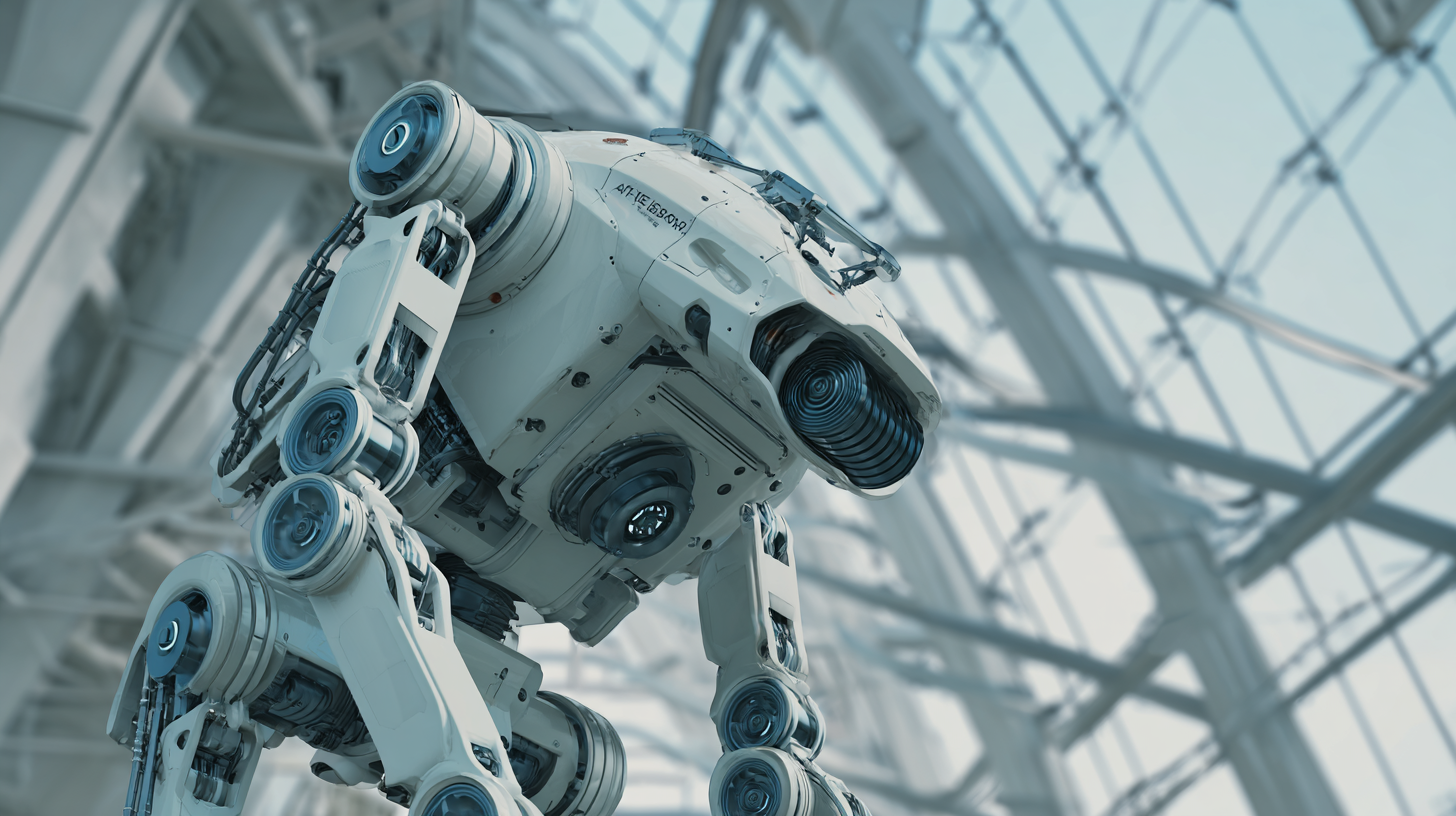

Understanding Construction Robots and Their Role in Modern Building Efficiency

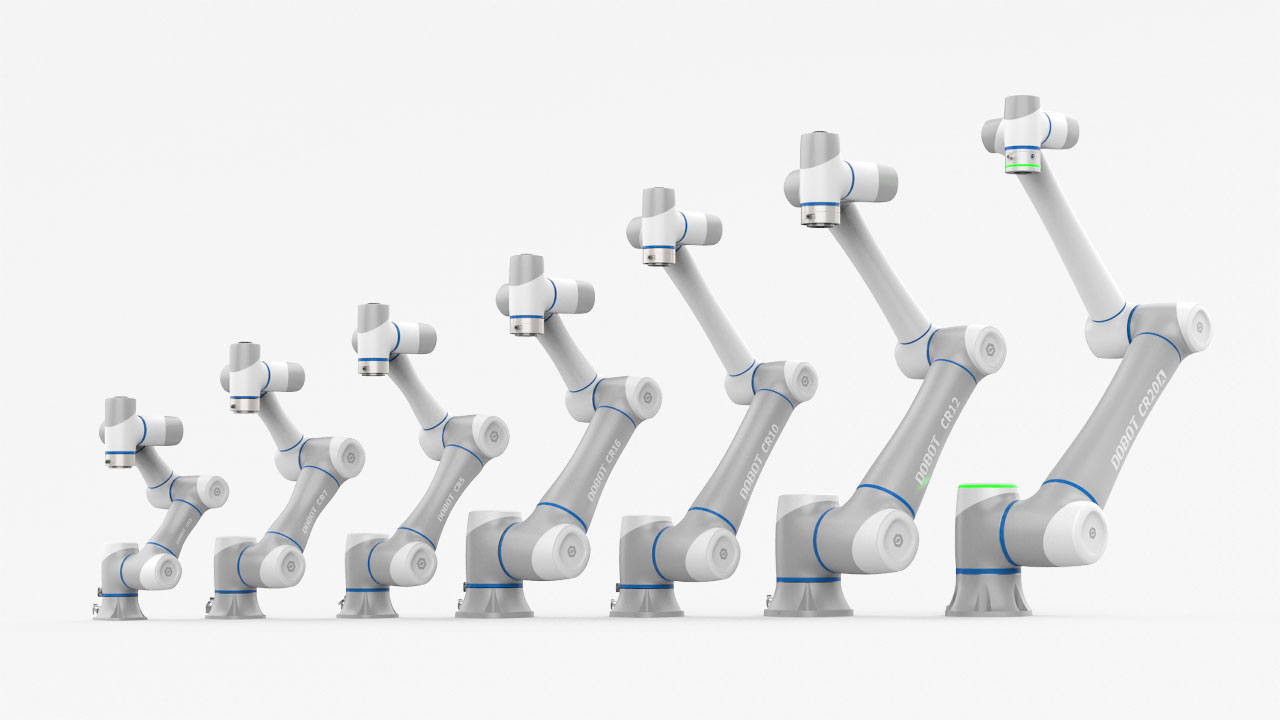

Construction robots are rapidly transforming

the landscape of modern building efficiency. These advanced machines are designed to tackle

various tasks, from bricklaying to site surveying, thereby reducing the time needed for

construction projects. By automating repetitive processes, construction robots not only enhance

productivity but also minimize human error, leading to higher quality builds. Their ability to

operate in harsh conditions and perform tedious tasks allows human workers to focus on

complex problem-solving and innovative design elements.

Moreover, construction robots contribute significantly to safety on job sites. By taking over

hazardous tasks such as demolition and heavy lifting, they reduce the risk of accidents and

injuries for workers. The integration of robots also promotes sustainability

in construction. Many robots are programmed to optimize material usage and energy consumption,

reducing waste and the environmental impact of building projects. As the industry continues to

evolve, understanding the role of construction robots becomes essential for leveraging their

capabilities to enhance overall building efficiency.

Identifying Key Areas for Automation in the Construction Process

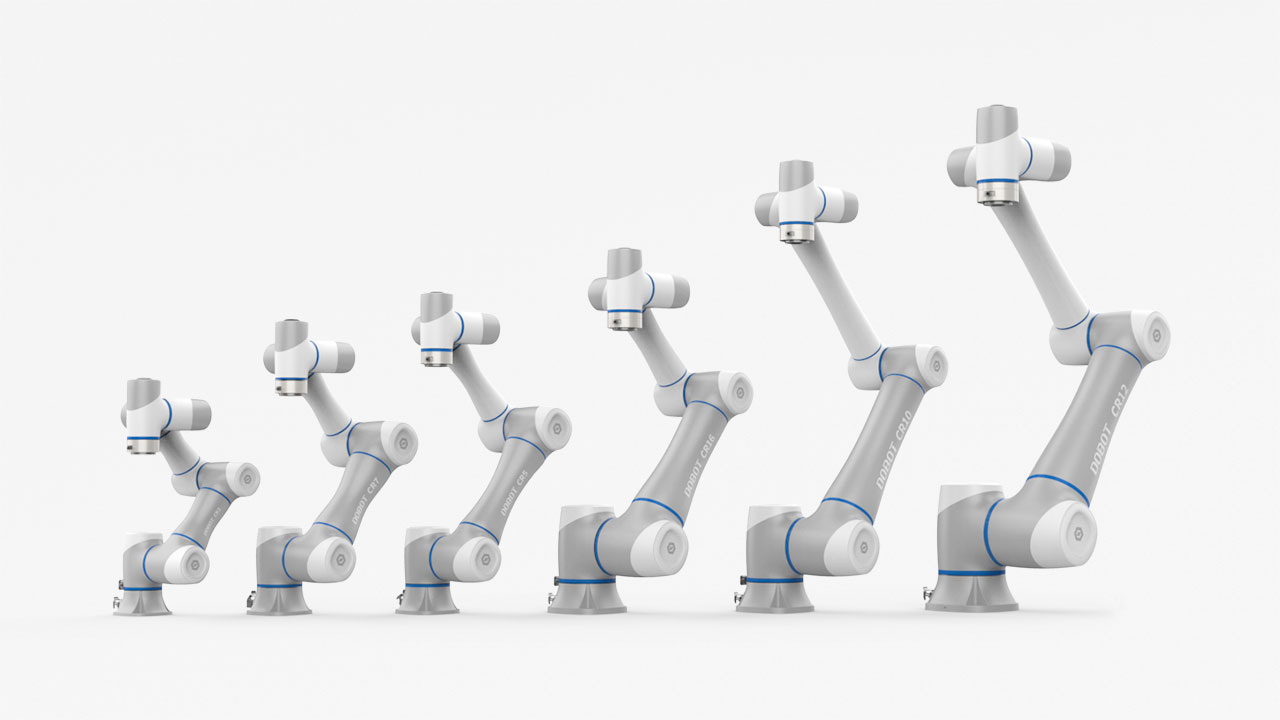

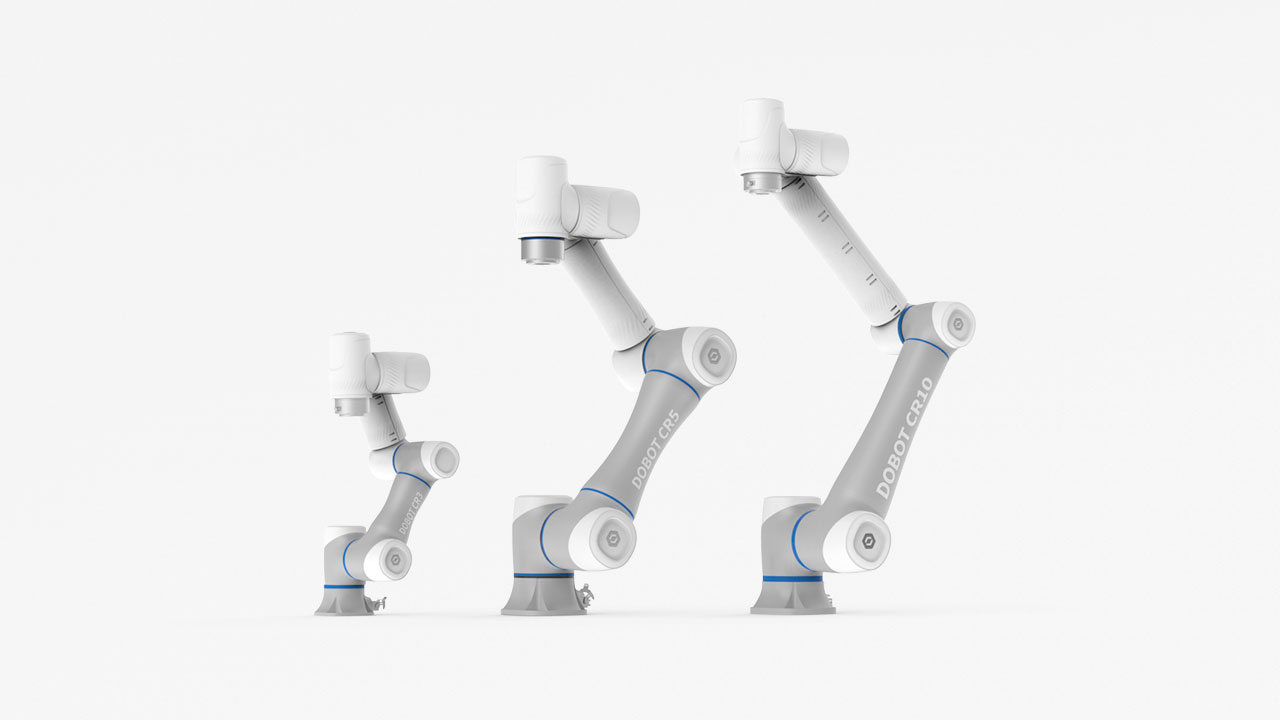

In the rapidly evolving landscape of modern construction, identifying key areas for automation is vital to enhance building efficiency. One significant area is material handling. Implementing construction robots for transporting materials on-site can dramatically reduce the time spent on logistics, minimize labor costs, and increase safety. Autonomous vehicles equipped with advanced navigation systems can traverse complex job sites, delivering supplies directly where they are needed, thus streamlining workflows.

Another area ripe for automation is routine tasks such as bricklaying and concrete pouring. Robots designed specifically for these functions can work with greater speed and precision than their human counterparts, ensuring higher quality finishes and consistent results. By taking over repetitive and labor-intensive tasks, robots not only improve efficiency but also allow skilled workers to focus on more complex activities that require human intuition and craftsmanship. Embracing automation in these key areas will significantly contribute to a more efficient construction process, ultimately paving the way for innovative building solutions.

Implementing Robotics for Enhanced Safety and Reduced Labor Costs

The integration of robotics in the construction industry is transforming the landscape by enhancing safety and reducing labor costs. With global market projections showing a significant rise in the adoption of artificial intelligence and robotic technologies, industries are reaping the benefits of increased efficiency and productivity. As the sector grapples with challenges such as labor shortages and supply chain disruptions, the implementation of advanced robotics plays a critical role in maintaining operational continuity and safety.

The current trends highlight the shift towards automation, with humanoid robots emerging as a key player in manufacturing sectors. These robots can significantly cut down on labor costs while simultaneously improving workplace safety by taking on hazardous tasks. For instance, humanoid robots capable of autonomous operations can self-maintain, such as replacing batteries without external assistance, thus ensuring uninterrupted workflow. This evolution not only addresses immediate labor issues but also positions the industry to innovate and adapt in a rapidly changing economic environment, marking a new era of construction efficiency.

Integrating Advanced Technologies with Construction Robotics for Optimal Performance

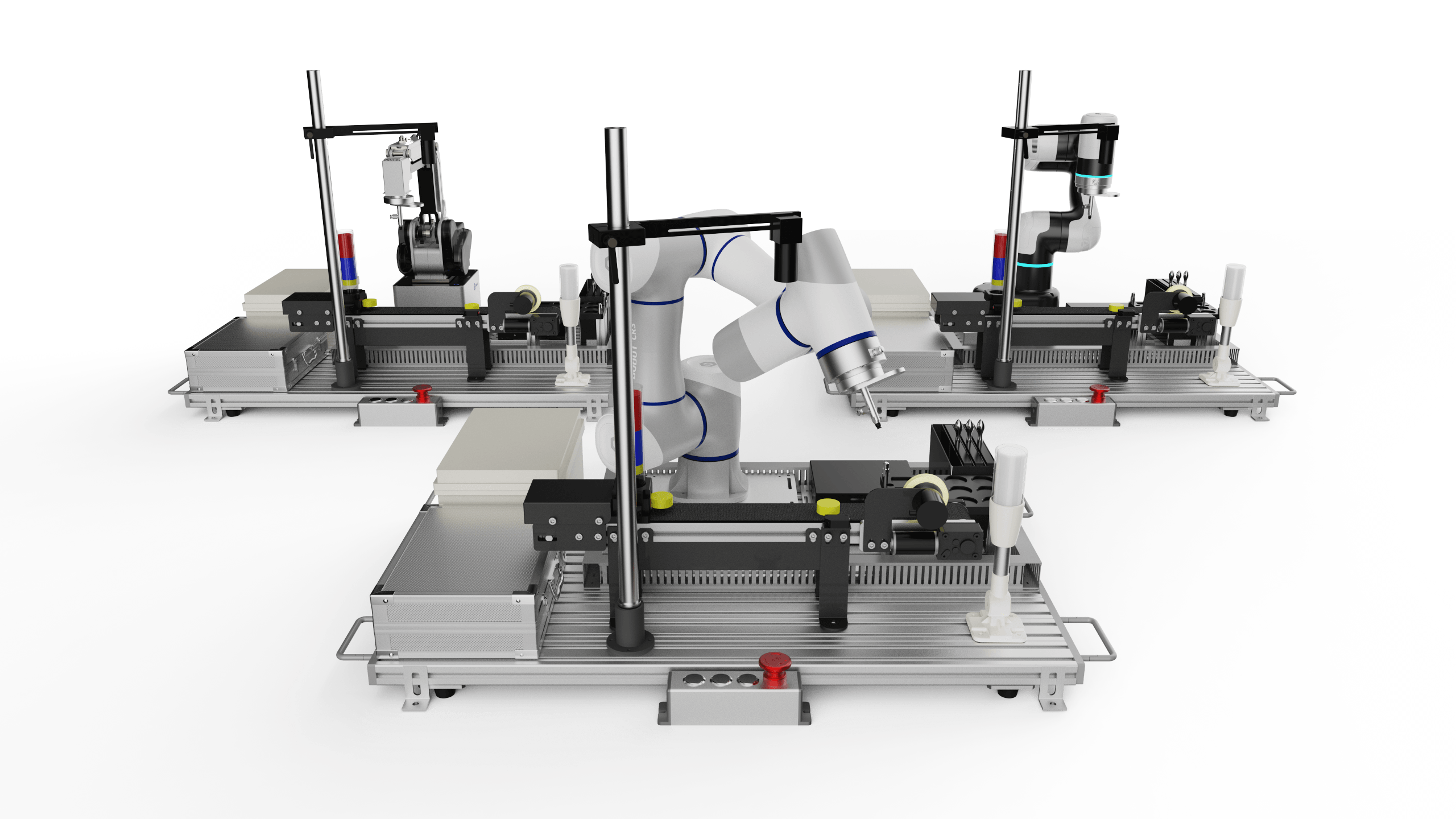

The integration of advanced technologies with construction robotics represents a transformative shift in the modern building industry. By employing artificial intelligence, machine learning, and the Internet of Things, construction robots can enhance efficiency, reduce costs, and minimize human error. These innovations allow for real-time data analysis and decision-making, enabling robotic systems to optimize workflows and adapt to changing project demands seamlessly. For instance, drones equipped with sensors can survey sites faster than traditional methods, while autonomous vehicles can transport materials, reducing labor costs and improving safety on-site.

The integration of advanced technologies with construction robotics represents a transformative shift in the modern building industry. By employing artificial intelligence, machine learning, and the Internet of Things, construction robots can enhance efficiency, reduce costs, and minimize human error. These innovations allow for real-time data analysis and decision-making, enabling robotic systems to optimize workflows and adapt to changing project demands seamlessly. For instance, drones equipped with sensors can survey sites faster than traditional methods, while autonomous vehicles can transport materials, reducing labor costs and improving safety on-site.

Furthermore, the convergence of building information modeling (BIM) with robotic automation creates a synergistic effect that streamlines construction processes. Robots programmed to follow BIM can execute precise tasks such as bricklaying or painting, ensuring consistency and high-quality output. This level of integration not only boosts productivity but also enables project managers to monitor progress with unprecedented accuracy. As construction companies embrace these advanced technologies, the potential for efficiency gains and enhanced performance becomes increasingly apparent, setting new standards for the industry as a whole.

Measuring the Impact of Robotics on Sustainability and Project Timelines in Construction

The integration of construction robots in the modern industry significantly impacts sustainability and project timelines. By automating repetitive and labor-intensive tasks, robots can enhance efficiency, reduce waste, and minimize the carbon footprint associated with construction activities. For instance, robotic arms can aid in bricklaying, allowing for faster construction with precise material usage.

Tips for leveraging robotics in construction include conducting a thorough assessment of workflow processes to identify areas where automation can have the most significant impact. Additionally, investing in training for workers will ensure they can effectively collaborate with robots, maximizing productivity while maintaining a focus on safety and quality.

Another key factor is to prioritize the use of eco-friendly materials and sustainable practices when deploying robotic technologies. This not only supports environmental goals but also aligns with the increasing demand for sustainable building solutions in the industry. Encouraging collaboration between robotics manufacturers and construction firms can lead to innovative solutions that further enhance efficiency and sustainability in projects.

How to Enhance Building Efficiency with Construction Robots in the Modern Industry

| Dimension |

Pre-Robotics Implementation |

Post-Robotics Implementation |

Percentage Improvement |

| Construction Time |

12 months |

8 months |

33.33% |

| Labor Costs |

$400,000 |

$250,000 |

37.5% |

| Material Waste |

20% |

10% |

50% |

| Overall Project Costs |

$2,000,000 |

$1,500,000 |

25% |

According to the "World Robotics Report 2021", the global market for construction automation is projected to reach $1.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 14.5%. Furthermore, McKinsey & Company reports that integrating robotics into construction processes can lead to a productivity increase of up to

According to the "World Robotics Report 2021", the global market for construction automation is projected to reach $1.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 14.5%. Furthermore, McKinsey & Company reports that integrating robotics into construction processes can lead to a productivity increase of up to

The integration of advanced technologies with construction robotics represents a transformative shift in the modern building industry. By employing artificial intelligence, machine learning, and the Internet of Things, construction robots can enhance efficiency, reduce costs, and minimize human error. These innovations allow for real-time data analysis and decision-making, enabling robotic systems to optimize workflows and adapt to changing project demands seamlessly. For instance, drones equipped with sensors can survey sites faster than traditional methods, while autonomous vehicles can transport materials, reducing labor costs and improving safety on-site.

The integration of advanced technologies with construction robotics represents a transformative shift in the modern building industry. By employing artificial intelligence, machine learning, and the Internet of Things, construction robots can enhance efficiency, reduce costs, and minimize human error. These innovations allow for real-time data analysis and decision-making, enabling robotic systems to optimize workflows and adapt to changing project demands seamlessly. For instance, drones equipped with sensors can survey sites faster than traditional methods, while autonomous vehicles can transport materials, reducing labor costs and improving safety on-site.