Elevating Global Standards in Packaging Robot Innovation for Enhanced Efficiency

The packaging industry is undergoing a significant transformation, with the rise of automation and the integration of advanced technologies playing a pivotal role in enhancing operational efficiency. According to a report by MarketsandMarkets, the global packaging automation market is projected to reach USD 69.3 billion by 2024, growing at a CAGR of 7.4% from 2019. This growth is driven by the increasing demand for speedy packaging processes and improved supply chain efficiency. As businesses seek to streamline their operations, Packaging Robots have emerged as a critical component, offering solutions that not only reduce labor costs but also enhance precision and consistency in packaging tasks.

As the competition intensifies across various sectors, the adoption of Packaging Robots has become a key strategy for companies aiming to elevate their operational standards. The International Federation of Robotics reported that the use of industrial robots, including packaging applications, has seen a substantial increase, with over 2.7 million units installed globally by 2020. This trend underscores the necessity for innovation in packaging robot technology, as it directly impacts productivity and profit margins. In this blog, we will delve into the advancements in packaging robot innovation and explore how these technologies are setting new benchmarks for efficiency in the industry.

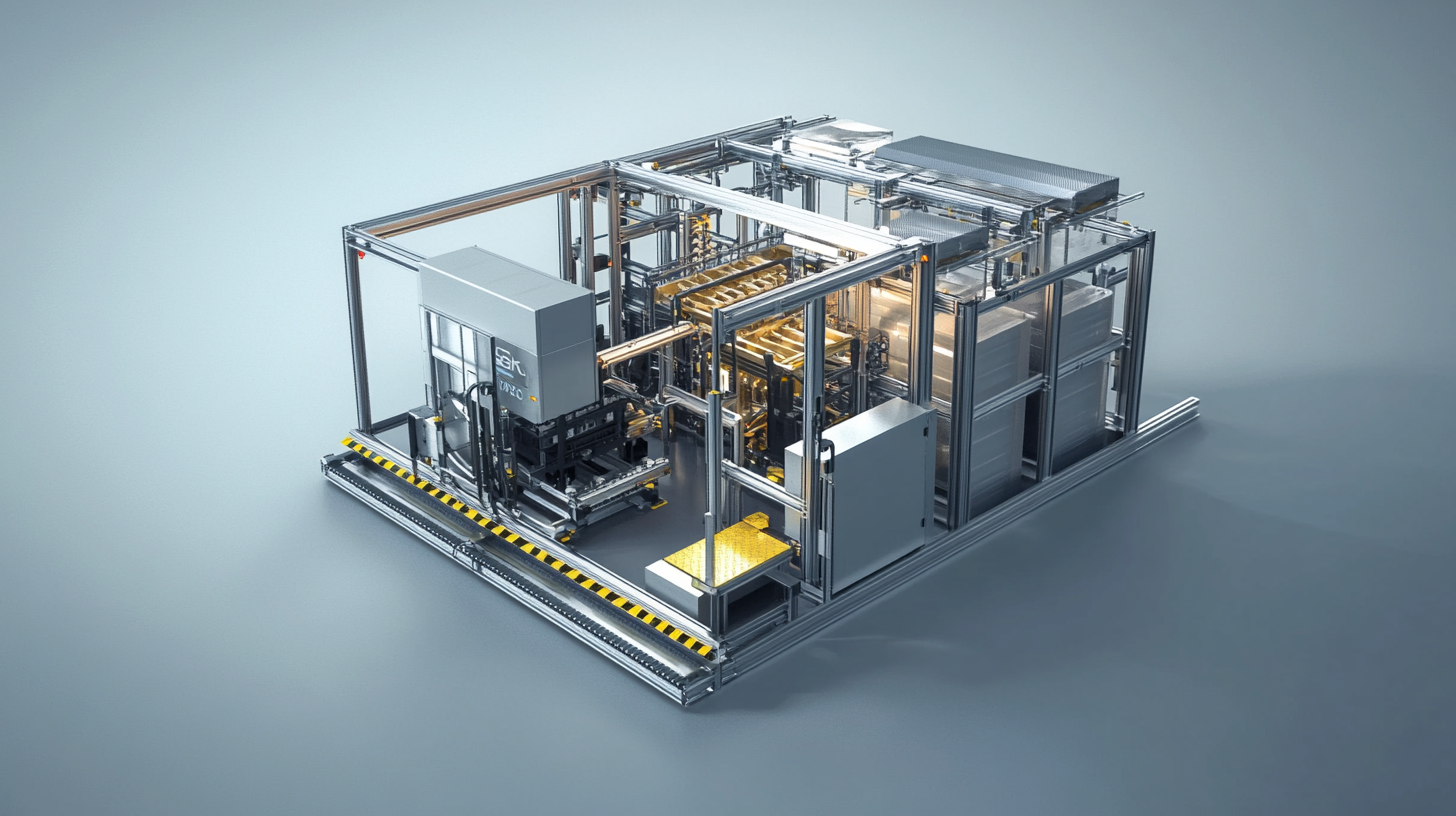

Global Packaging Robot Market Growth and Projections Through 2027

The global packaging robot market is poised for significant growth, with projections indicating a compound annual growth rate (CAGR) of approximately 12% from 2022 to 2027. Factors contributing to this robust expansion include advancements in automation technology, the increasing demand for efficiency in packaging processes, and the rising need for flexibility in production lines. According to a recent report by MarketsandMarkets, the market size for packaging robots is expected to reach nearly $8 billion by 2027, underscoring the importance of robotics in modern manufacturing.

One of the driving forces behind this growth is the shift towards Industry 4.0. Manufacturers are increasingly adopting smart packaging solutions that integrate robotics with artificial intelligence and machine learning. This technological evolution not only enhances operational efficiency but also allows for real-time data processing and improved decision-making in packaging operations. In sectors such as food and beverage, pharmaceuticals, and consumer goods, the use of packaging robots has been shown to reduce operational costs by up to 30% while simultaneously increasing output.

Furthermore, the demand for sustainable packaging solutions is influencing the packaging robot market. As businesses strive to meet environmental regulations and consumer preferences for eco-friendly products, robotics in packaging can facilitate the efficient use of materials and reduce waste. According to the European Packaging and Processing Machinery Association, about 75% of manufacturers are considering or have already implemented robotic systems to enhance their sustainability initiatives, indicating a strong trend towards eco-conscious practices in packaging.

Key Innovations Driving Efficiency in Packaging Robotics Technology

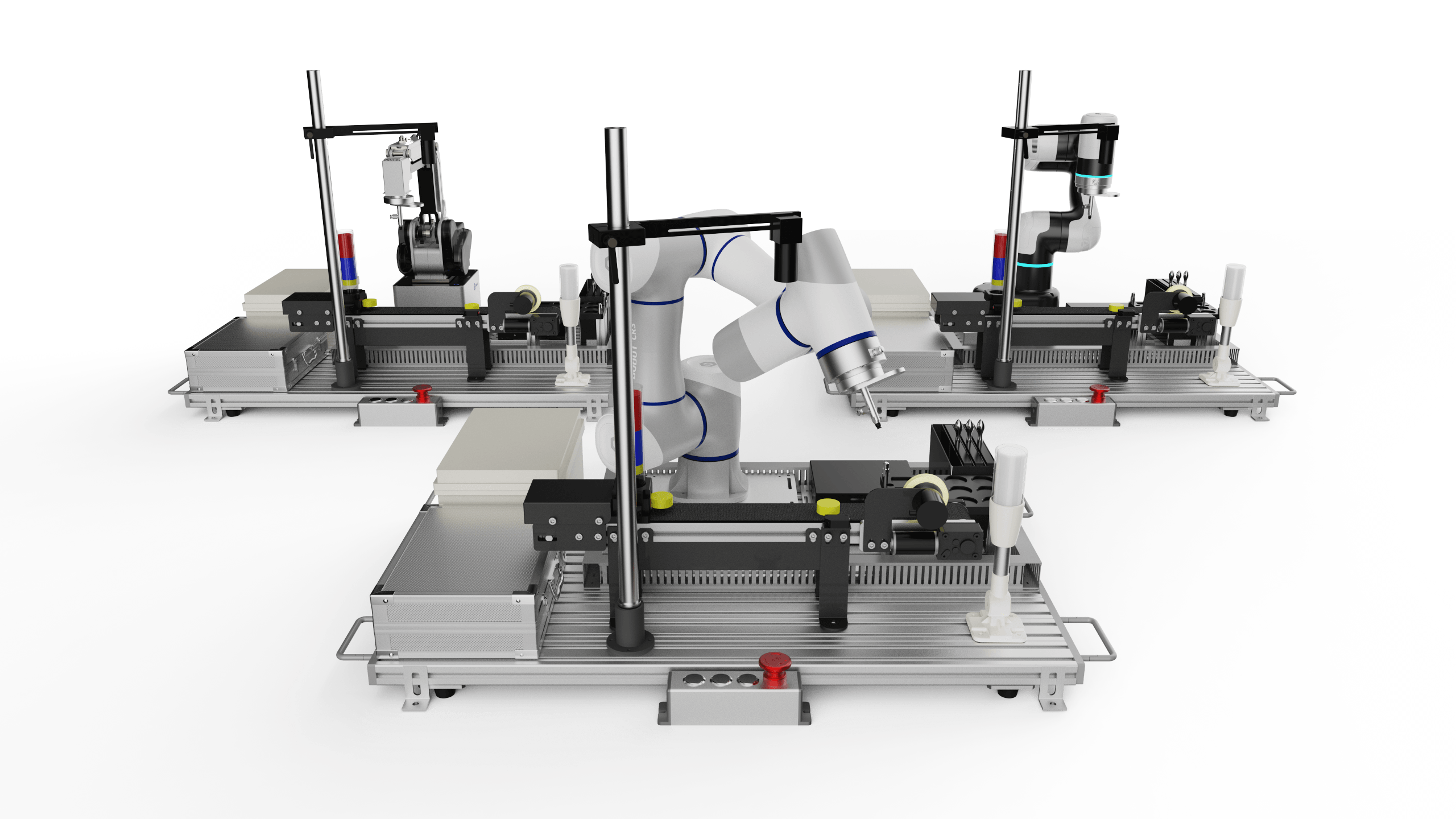

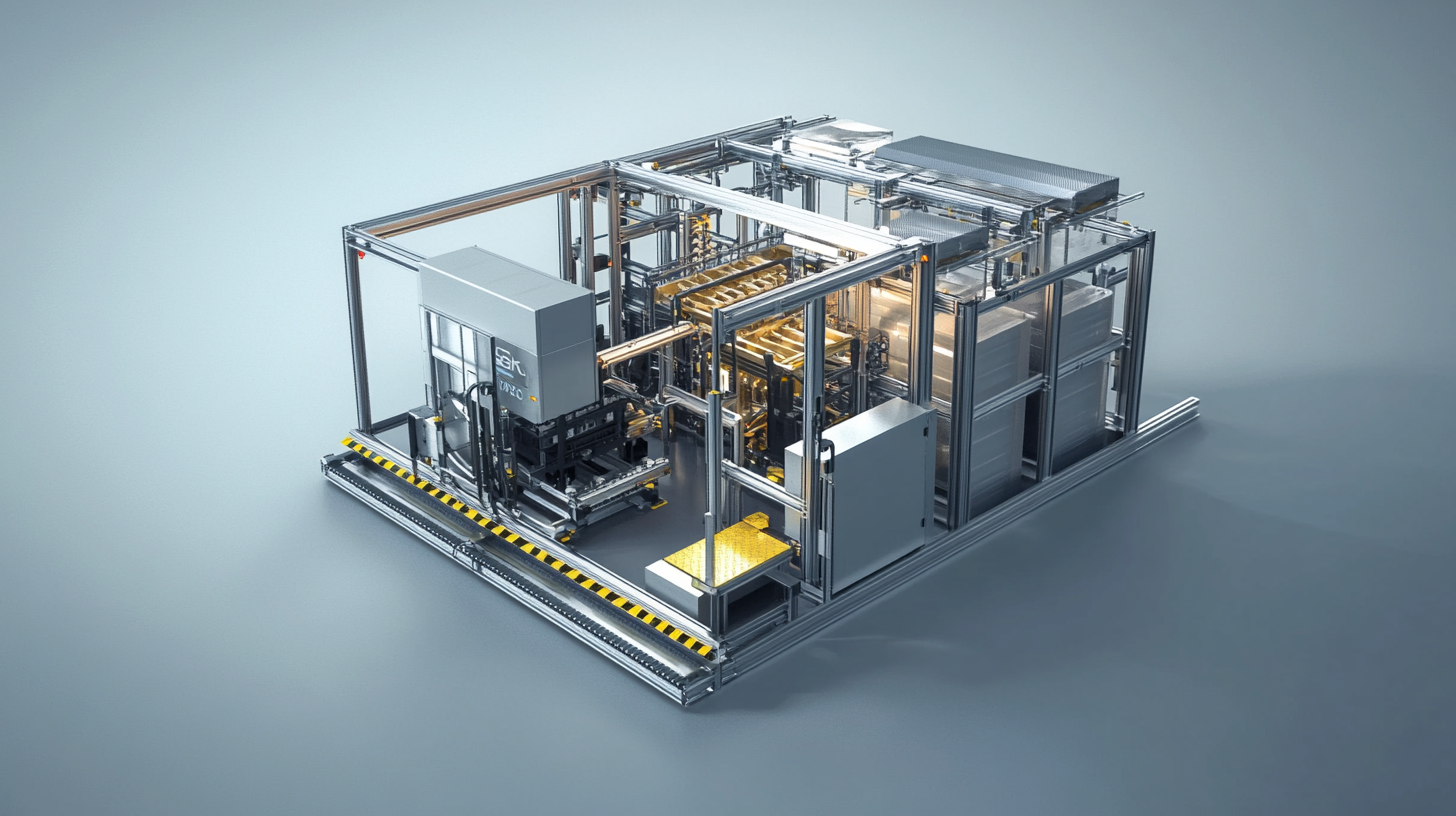

The packaging robotics technology landscape is witnessing unprecedented innovations that are revolutionizing efficiency in manufacturing processes. As industries shift from traditional methods to intelligent manufacturing, the integration of advanced robotic systems plays a pivotal role. The rapid development of industrial robots allows manufacturers to optimize production lines by automating processes once reliant on human intervention. This transformation is not just about increased output; it's also about enhanced precision and reduced errors, which are critical in today's competitive marketplace.

Recent advancements, showcased in digital manufacturing hubs, emphasize the importance of real-time data analytics in driving productivity. For instance, companies like Feicheng Changsheng Special Graphite Co. are utilizing large digital displays to monitor and analyze production data instantaneously. This level of insight allows for more informed decision-making, ultimately leading to smoother operations and efficient resource allocation. The synergy between robotics and digital technology is setting new benchmarks in packaging efficiency, allowing businesses to meet growing consumer demands with agility and accuracy.

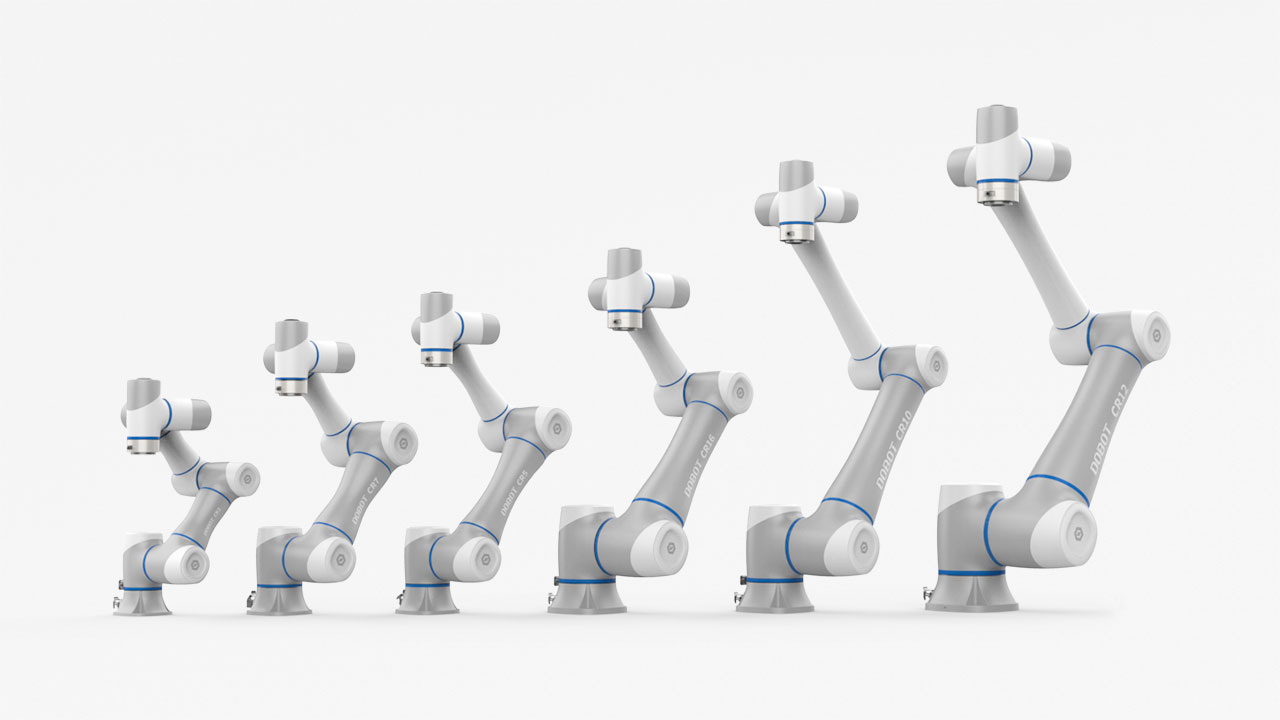

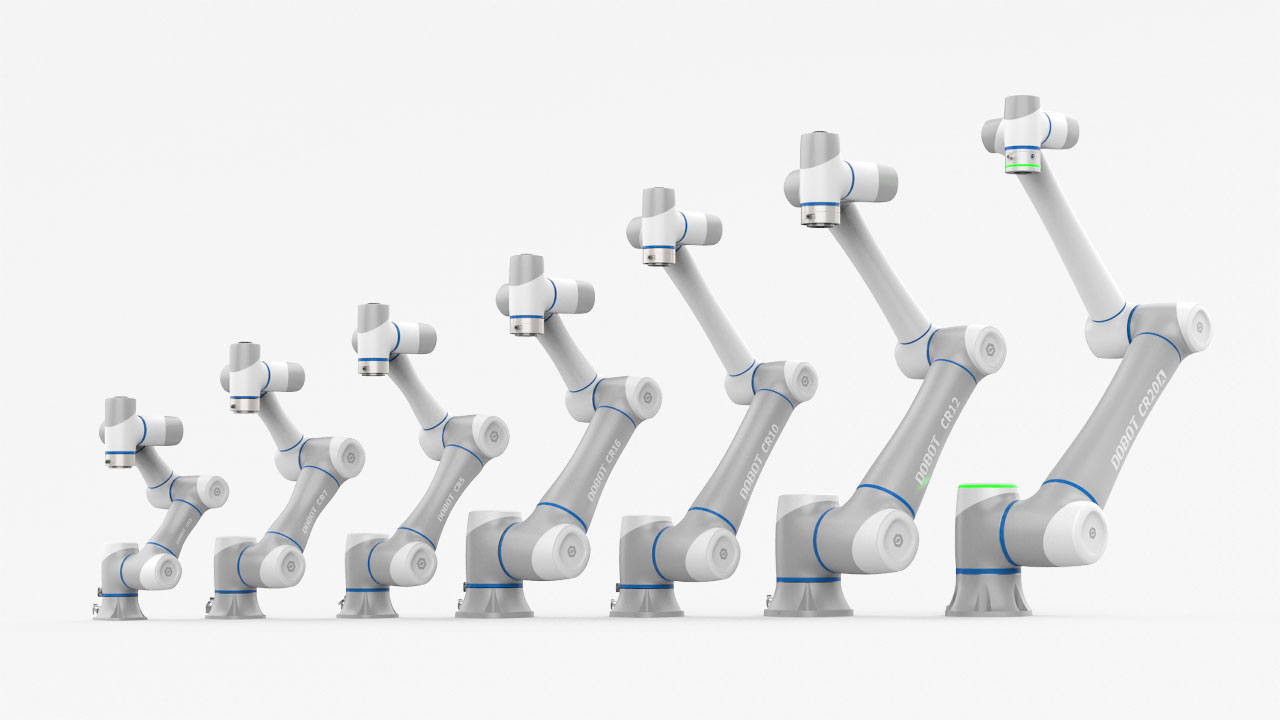

As the packaging robotics market continues to expand, key innovations such as artificial intelligence, machine learning, and collaborative robotics are increasingly being adopted. These technologies not only enhance the capabilities of packaging robots but also facilitate better collaboration between machines and human workers. This integrated approach not only boosts productivity but also lays the groundwork for sustainable practices within the packaging industry, further aligning with global standards for innovation and efficiency.

Case Studies: Successful Implementation of Packaging Robots in Various Industries

In the ever-evolving landscape of manufacturing and logistics, the implementation of packaging robots has shown promising results across various industries. A recent report by the International Federation of Robotics (IFR) indicates that the global market for industrial robots in packaging is projected to reach $14 billion by 2025, reflecting a compound annual growth rate (CAGR) of 25.4%. This surge can be attributed to the increasing demand for efficiency, accuracy, and safety in packaging operations.

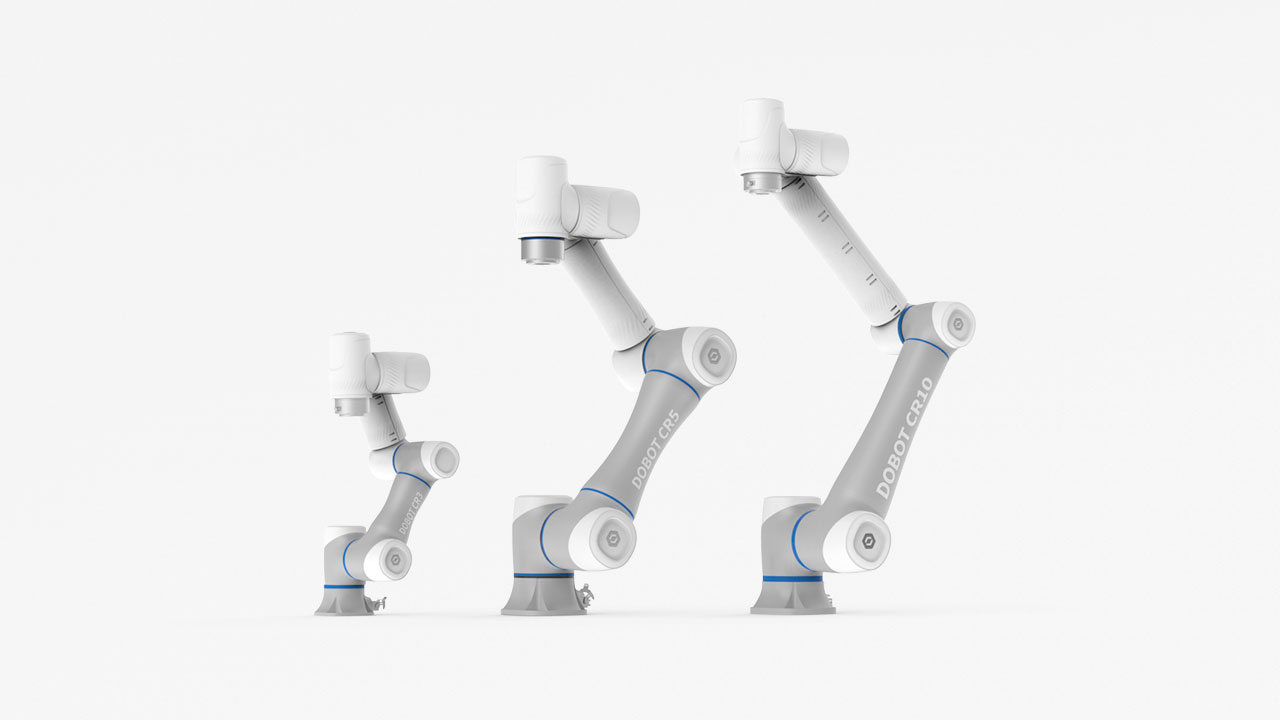

One compelling case study comes from the food and beverage sector, where a leading company integrated robotic packaging solutions to streamline their operation. Through deploying collaborative robots, or cobots, they achieved a significant reduction in packaging time by 30%, while also minimizing labor costs by approximately 20%. These statistics highlight the potential of robotic technology to not only enhance efficiency but to also drive down operational expenses, ensuring a more competitive market stance.

In the consumer electronics industry, another notable success story showcases the deployment of automated packing solutions that utilize advanced vision systems. A major electronics manufacturer reported that the introduction of robotic systems into their packaging line resulted in a 50% increase in throughput. Moreover, the precision of robots helped reduce packaging errors by over 90%, showcasing how technology can improve product integrity and customer satisfaction.

These examples illustrate that the intelligent integration of packaging robots across various sectors not only bolsters operational efficiency but also elevates quality standards. As industries continue to adapt to these innovations, the data suggests a transformation that companies cannot afford to overlook.

Impact of Robotics on Labor Costs and Productivity in Packaging Operations

The integration of robotics in packaging operations has significantly reshaped labor dynamics, particularly in terms of costs and productivity. As the demand for efficiency and speed in packaging continues to rise, manufacturers are increasingly turning to robotic solutions to meet these challenges. Robotics streamlines various processes, from sorting and packing to palletizing and shipping, allowing companies to optimize their operations with minimal human intervention. This shift not only reduces labor costs but also minimizes the likelihood of human error, leading to a more reliable output.

Furthermore, the impact of these advancements is evident in the overall productivity of packaging lines. By delegating repetitive tasks to robots, human workers can focus on higher-value responsibilities that require critical thinking and problem-solving skills. This reallocation of labor not only enhances job satisfaction among employees but also leads to sharper operational efficiency. The recent surge in the packaging robot market reflects this trend, with companies investing heavily in automation technologies to keep pace with consumer demands. As businesses continue to realize the benefits of robotics, we can expect a further evolution in packaging operations that leverages technology to create a more sustainable and efficient industry.

Sustainability in Packaging Automation: Trends and Future Directions

The landscape of sustainability in packaging automation is rapidly evolving, reflecting a growing commitment to environmentally friendly practices across various sectors. The industrial packaging market is poised for significant growth, driven by innovations that enhance efficiency while addressing sustainability concerns. By 2034, the sustainable pharmaceutical packaging market is expected to reach a staggering $76 billion, underscoring the increasing demand for eco-friendly solutions in this critical sector. As consumer preferences shift towards sustainable options, the packaging industry is adapting by integrating recyclable materials, minimizing waste, and adopting advanced technologies.

In addition to pharmaceuticals, the rapid expansion of e-commerce is catalyzing a rise in reusable packaging solutions. Projected to exceed $7.8 billion by 2034, reusable e-commerce packaging is gaining traction as businesses seek to reduce their carbon footprint amidst growing regulatory pressures. The demand for sustainability is further echoed in the fruit and vegetable processing equipment market, which anticipates a compound annual growth rate (CAGR) of over 6.3%. This surge is primarily driven by the need for convenient, processed food items that align with modern consumption patterns, emphasizing efficiency and environmental responsibility.

As we look towards 2034, the trends in packaging automation suggest a shift towards a more circular economy, where innovation in materials and design not only enhances operational productivity but also prioritizes sustainability. The ongoing advancements in technologies that support these initiatives will redefine industry standards, ultimately contributing to a greener, more efficient future for packaging.