Ultimate Guide to Choosing the Best Industrial Robots for Your Manufacturing Needs

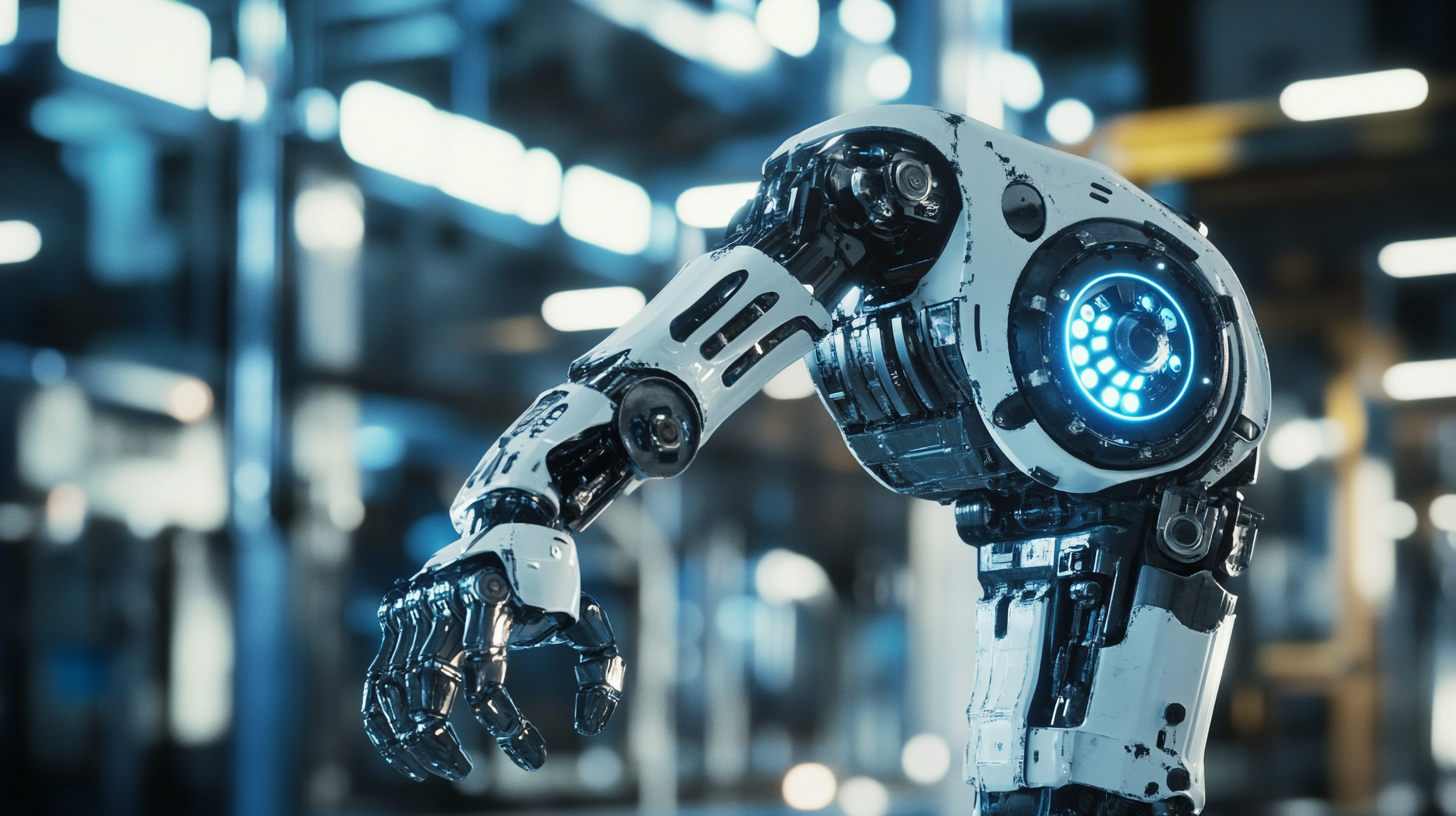

In today's rapidly evolving manufacturing landscape, the integration of Industrial Robots is not just a luxury but a necessity for businesses striving to enhance efficiency and productivity. As companies seek to remain competitive, understanding the different types of Industrial Robots and their specific applications becomes crucial. This ultimate guide aims to demystify the process of choosing the best Industrial Robots for your unique manufacturing needs.

In today's rapidly evolving manufacturing landscape, the integration of Industrial Robots is not just a luxury but a necessity for businesses striving to enhance efficiency and productivity. As companies seek to remain competitive, understanding the different types of Industrial Robots and their specific applications becomes crucial. This ultimate guide aims to demystify the process of choosing the best Industrial Robots for your unique manufacturing needs.

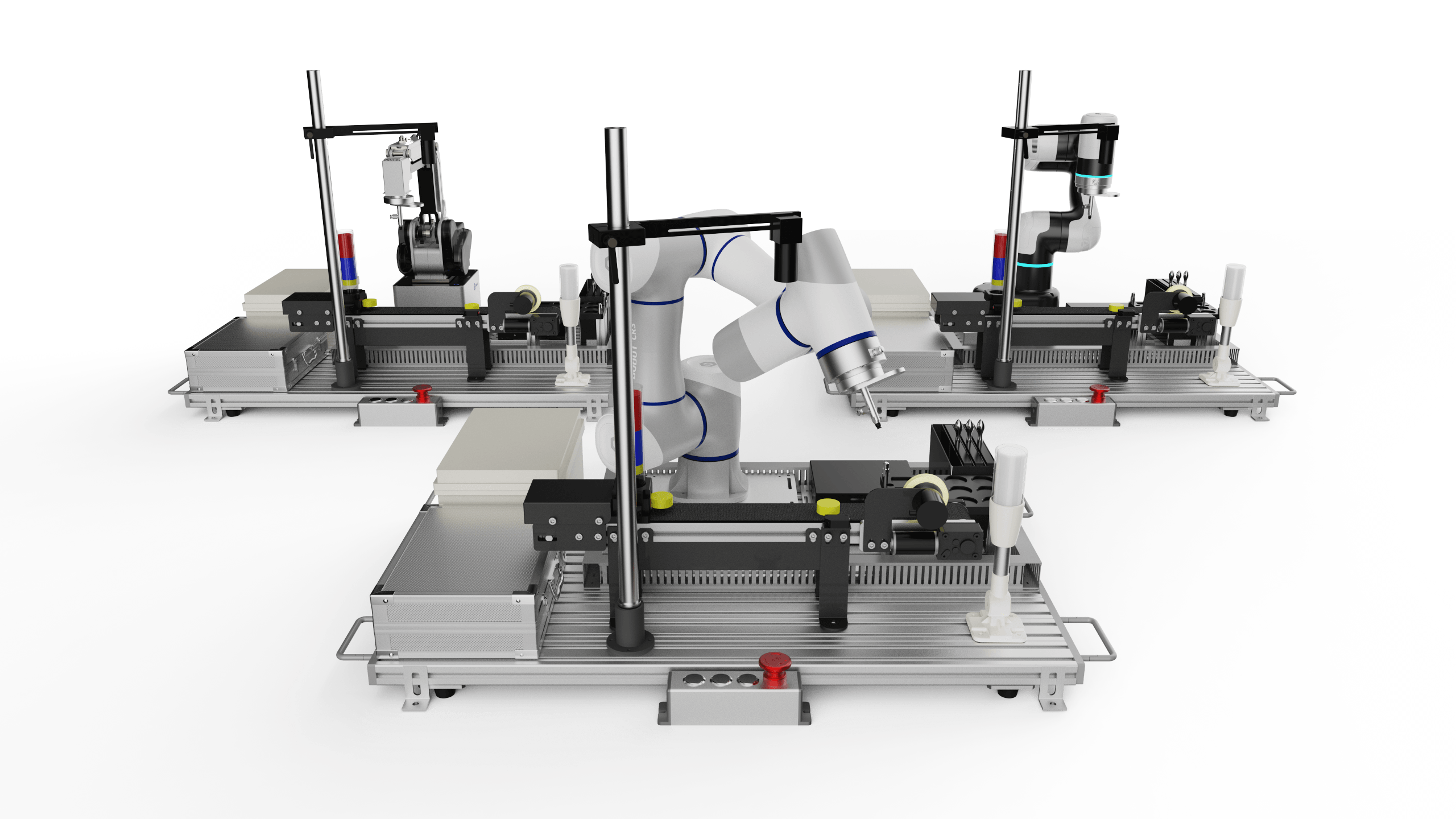

From articulated arms to collaborative robots, each type offers distinct advantages and capabilities tailored to various tasks. Whether you are looking to automate repetitive tasks or improve precision in complex operations, selecting the right Industrial Robots can significantly impact your production outcomes.

Join us as we explore the fundamental aspects and critical factors to consider in your journey towards advanced automation.

Factors to Consider When Selecting Industrial Robots for Manufacturing Efficiency

When selecting industrial robots to enhance manufacturing efficiency, there are several critical factors to consider, especially in a rapidly growing market expected to reach $211.1 billion by 2034. First, assess the specific needs of your manufacturing processes. Different robots serve varied applications, from assembly to material handling. Choosing the right type of robot, whether articulated, collaborative, or mobile, can significantly impact productivity and operational flow.

Tips: Consider the integration capabilities of the robots with existing systems. Implementing robots that can seamlessly communicate with your machinery and software will reduce downtime and enhance workflow. Additionally, focus on the scalability of the robot solutions. Your manufacturing needs might evolve, so selecting flexible and upgradeable robots can provide long-term value.

Another vital aspect is the total cost of ownership. While initial investments in industrial robots can be significant, evaluating the potential return on investment through increased efficiency, reduced labor costs, and minimized errors is essential. Take advantage of ongoing innovations in battery technology, like wireless charging for mobile robots, which can lead to higher uptime and efficiency in production environments.

The Role of Industrial Robots in Enhancing Production Speed and Accuracy

In today's fast-paced manufacturing landscape, industrial robots play a crucial role in enhancing production speed and accuracy. According to a recent report by the International Federation of Robotics (IFR), global sales of industrial robots reached 486,000 units in 2020, and this number is projected to grow as more companies recognize the benefits of automation. By streamlining repetitive tasks, robots can operate at higher speeds and with greater precision than human workers, leading to significantly reduced cycle times and improved overall productivity.

Moreover, the integration of advanced technologies such as AI and machine learning in robotics has further amplified their efficacy. A study by McKinsey & Company indicates that automation could increase productivity in manufacturing by up to 20-25% by 2030. This transformation not only accelerates production lines but also enhances product quality by minimizing errors typically associated with manual handling. As manufacturers strive to stay competitive in a rapidly evolving industry, investing in industrial robots becomes essential for achieving operational excellence.

Key Technologies Driving the Next Generation of Industrial Robots

The landscape of industrial automation is rapidly evolving, driven by cutting-edge technologies that enhance the capabilities of modern industrial robots. At the forefront are advancements in artificial intelligence and machine learning, which enable robots to perform complex tasks with unprecedented accuracy and efficiency.

These intelligent systems can analyze vast amounts of data in real-time, allowing them to adapt to changing environments and optimize operations on the fly. This level of adaptability not only improves productivity but also significantly reduces downtime, giving manufacturers a competitive edge in the marketplace.

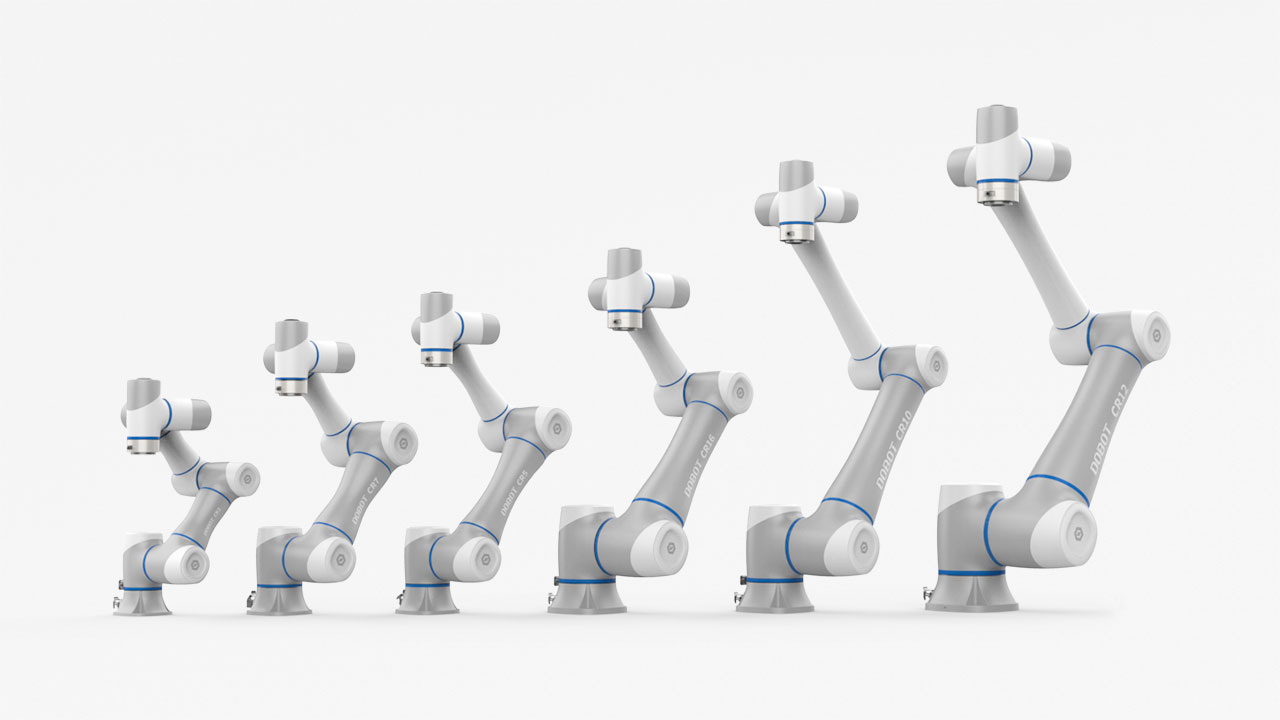

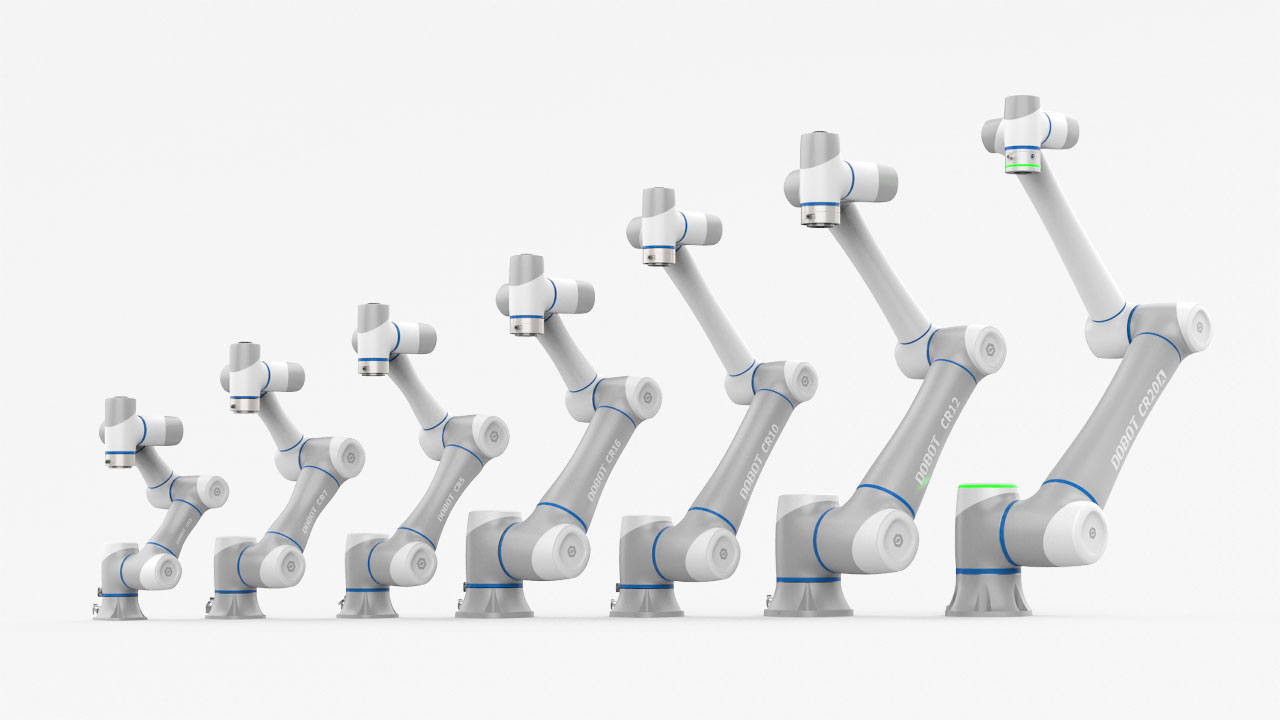

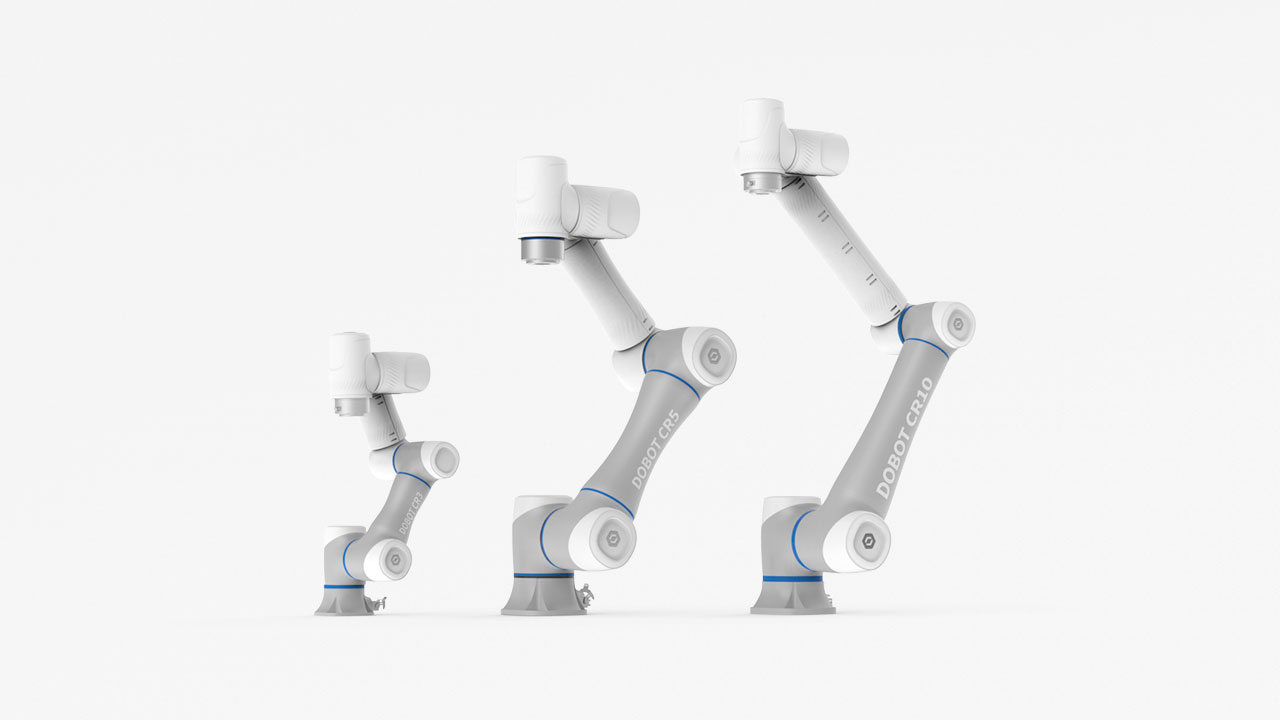

Another critical technology shaping the next generation of industrial robots is collaborative robotics, or cobots. Unlike traditional robots, which often operate in isolation, cobots are designed to work alongside human workers.

Equipped with advanced sensors and safety features, they can safely share workspaces and assist in tasks that require precision and speed. This collaboration enhances overall workflow and allows for greater flexibility in production processes. As industries continue to embrace automation, integrating these technologies will be essential for choosing the best industrial robots that meet specific manufacturing needs.

Comparative Analysis of Leading Industrial Robot Brands and Their Market Share

When selecting industrial robots for manufacturing needs, understanding the market dynamics and leading brands is crucial. According to the International Federation of Robotics (IFR), the global industrial robot market witnessed a significant growth of approximately 26% in 2021, driven by advancements in automation technologies. Among the leading players, companies such as Fanuc, Yaskawa, and ABB dominate the field, collectively holding over 40% of the market share. Fanuc, renowned for its reliability and cutting-edge technology, continues to lead with an impressive range of collaborative robots that enhance flexibility in production environments.

Comparative analysis reveals that while Fanuc excels in the global market, regional players like KUKA are making substantial inroads in Europe, accounting for an estimated 10% of the market share in this region alone. Additionally, innovations in artificial intelligence and machine learning have allowed companies like Universal Robots to capture the attention of small to medium-sized enterprises, with their user-friendly designs and scalable solutions. As the demand for automation continues to rise, understanding these market shares and brand strengths will be invaluable for manufacturers looking to optimize their operations.

Case Studies: Successful Implementation of Industrial Robots in Chinese Manufacturing

In recent years, Chinese manufacturing has seen a remarkable transformation through the successful implementation of industrial robots. Companies have utilized automated solutions to improve precision, enhance productivity, and streamline operations.

A standout example is a major automotive manufacturer that integrated robotic assembly lines, resulting in a 30% increase in production speed and a significant reduction in labor costs. Such case studies illustrate the tangible benefits that robots can offer to manufacturers seeking to maintain a competitive edge.

A standout example is a major automotive manufacturer that integrated robotic assembly lines, resulting in a 30% increase in production speed and a significant reduction in labor costs. Such case studies illustrate the tangible benefits that robots can offer to manufacturers seeking to maintain a competitive edge.

When selecting industrial robots, it’s crucial to align them with your specific manufacturing needs.

Tip 1: Assess your production volume and types of tasks to determine whether you need collaborative robots or heavy-duty models. This serves as the foundation for a successful robot integration strategy.

Tip 2: Pay attention to the scalability of the robots; selecting systems that can evolve with your business will ensure long-term benefits and adaptability.

Another noteworthy case is an electronics company that employed robotic arms for intricate part assembly. The implementation not only boosted output quality but also reduced the error rate by 40%.

Tip 3: Consider flexible automation solutions that can be easily reprogrammed for different functions, enabling your facility to pivot swiftly in response to market changes.

These insights reveal that with the right approach, industrial robots can significantly enhance manufacturing efficiency while adapting to future demands.

In today's rapidly evolving manufacturing landscape, the integration of

In today's rapidly evolving manufacturing landscape, the integration of

A standout example is a major automotive manufacturer that integrated robotic assembly lines, resulting in a 30% increase in production speed and a significant reduction in labor costs. Such case studies illustrate the tangible benefits that robots can offer to manufacturers seeking to maintain a competitive edge.

A standout example is a major automotive manufacturer that integrated robotic assembly lines, resulting in a 30% increase in production speed and a significant reduction in labor costs. Such case studies illustrate the tangible benefits that robots can offer to manufacturers seeking to maintain a competitive edge.