What is an Injection Machine Robot and How Does it Work?

Injection Machine Robots are revolutionizing the manufacturing sector. These machines automate the injection molding process, enhancing efficiency and precision. According to Dr. James Liu, a leading expert in automation, “Injection Machine Robots have transformed traditional manufacturing into a more agile and productive environment.”

The operation of an Injection Machine Robot involves several key segments. They work by melting plastic and injecting it into molds. This speeds up production while maintaining high quality. For instance, the robots can operate continuously, reducing downtime significantly. However, the reliance on robots also brings challenges. There is a learning curve for workers, and initial setup costs can be steep.

In conclusion, while Injection Machine Robots promise increased productivity, they also require careful consideration. Balancing automation with human expertise is essential. Industry professionals must constantly adapt and improve. The journey towards full automation is ongoing, and reflection on past implementations is crucial for future success.

What is an Injection Machine Robot?

An injection machine robot is an essential tool in manufacturing. It automates the injection molding process, which transforms raw plastic pellets into finished products. These robots work by injecting molten plastic into molds, then cooling and solidifying the material. This process ensures high precision and efficiency.

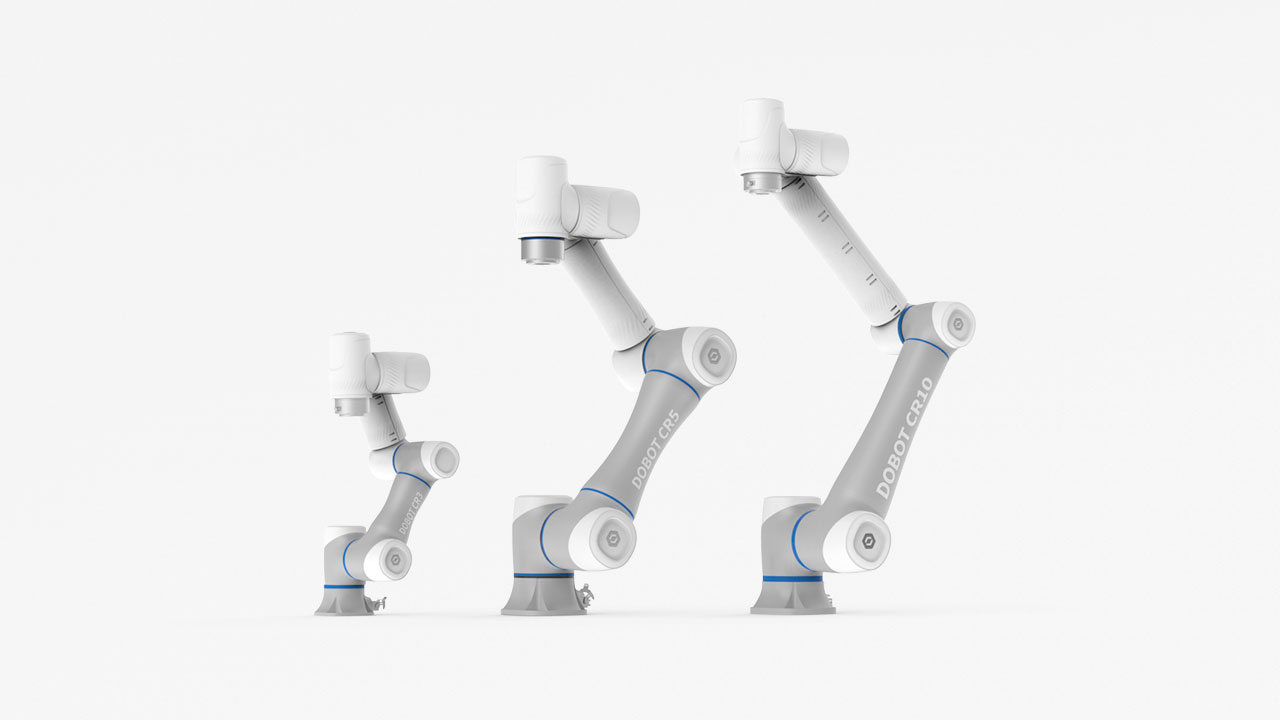

Operating an injection machine robot requires a solid understanding of its components. The main parts include the injection unit, clamping unit, and the control system. Each component plays a crucial role in the overall operation. Understanding these parts can help troubleshoot issues more effectively.

Tips: Keep the workspace clean. This helps prevent contamination of materials. Regular maintenance is crucial. Check the oil levels and lubricate moving parts often.

Moreover, programming these robots can present challenges. Slight miscalculations in settings can lead to defects. Repeating the same mistake can waste time and resources. Therefore, careful observation is needed.

Tips: Document changes in settings. This can help identify what worked well or what didn't. Training staff on troubleshooting can also minimize downtime and improve workflow.

Key Components of an Injection Machine Robot

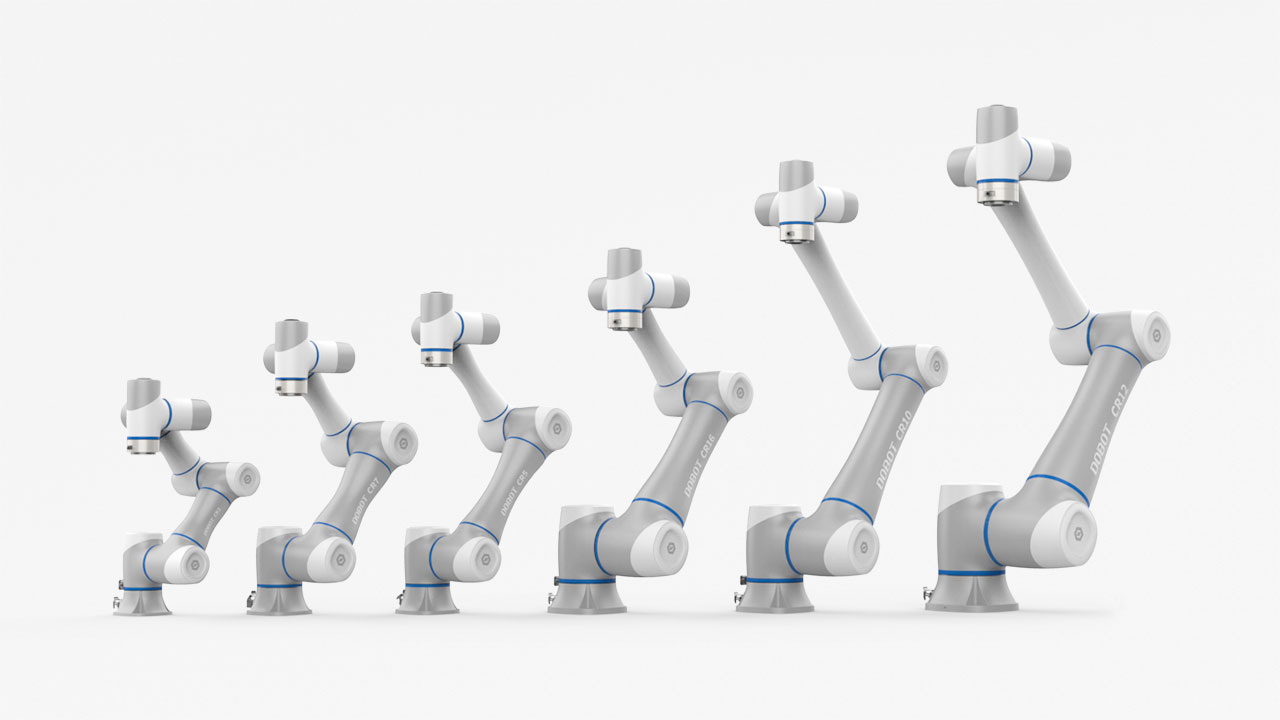

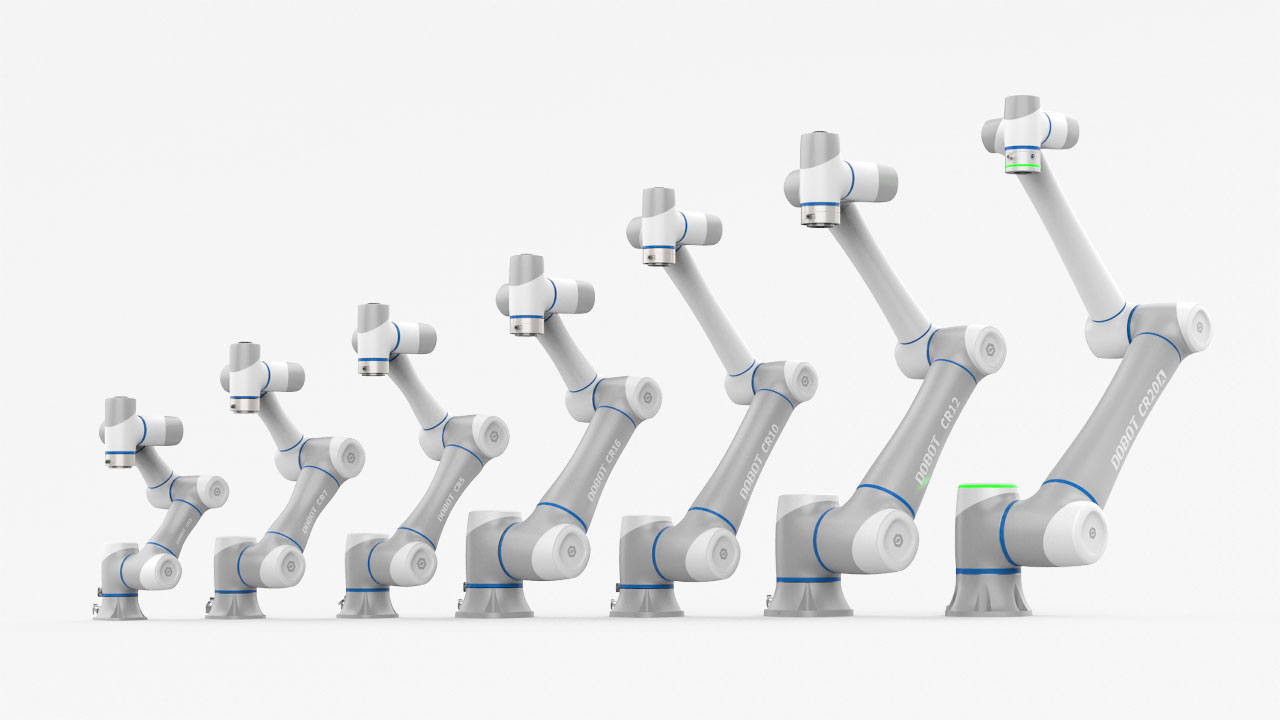

An injection machine robot is vital in manufacturing, especially for plastic and metal parts. Its efficiency comes from a few key components. The robot's frame holds everything in place. This structure supports movement and stability during operation. A precise motor controls the movement, ensuring accuracy in every phase. According to industry reports, automation in injection molding increases productivity by 30%.

The injection unit is critical. It melts raw materials and injects them into molds. This process demands high pressure and temperature control. Faulty temperature regulation can lead to defects in the final product. Studies indicate that 25% of production issues stem from poor injection quality. An effective cooling system follows the injection phase. Cooling solidifies the part, enabling quicker cycle times.

Another essential part is the control system. It monitors and adjusts various parameters in real time. A delay or malfunction in this system can lead to significant downtime. Data suggests that inconsistent control can increase waste by up to 15%. Constant evaluation of each component's performance is crucial. Improvements can lead to a more efficient process, reducing errors. Each element works together to enhance the overall function but requires careful analysis and adjustments.

What is an Injection Machine Robot and How Does it Work? - Key Components of an Injection Machine Robot

| Component | Function | Materials Used | Typical Applications |

| Injection Unit | Melts and injects plastic material into the mold | Steel, Aluminum | Automotive parts, Household items |

| Clamping Unit | Holds the mold closed during injection process | Cast Iron, Steel | Packaging, Toys |

| Control System | Controls machine operations and settings | Electronics, Plastics | Consumer Electronics, Medical Devices |

| Hydraulic System | Provides force to the clamping and injection units | Hydraulic Fluids, Metal Components | Heavy Equipment, Industrial Detailing |

| Temperature Control System | Maintains the temperature of the mold and material | Copper, Aluminum | Food Packaging, Aerospace Components |

How Injection Machine Robots Operate: The Process Explained

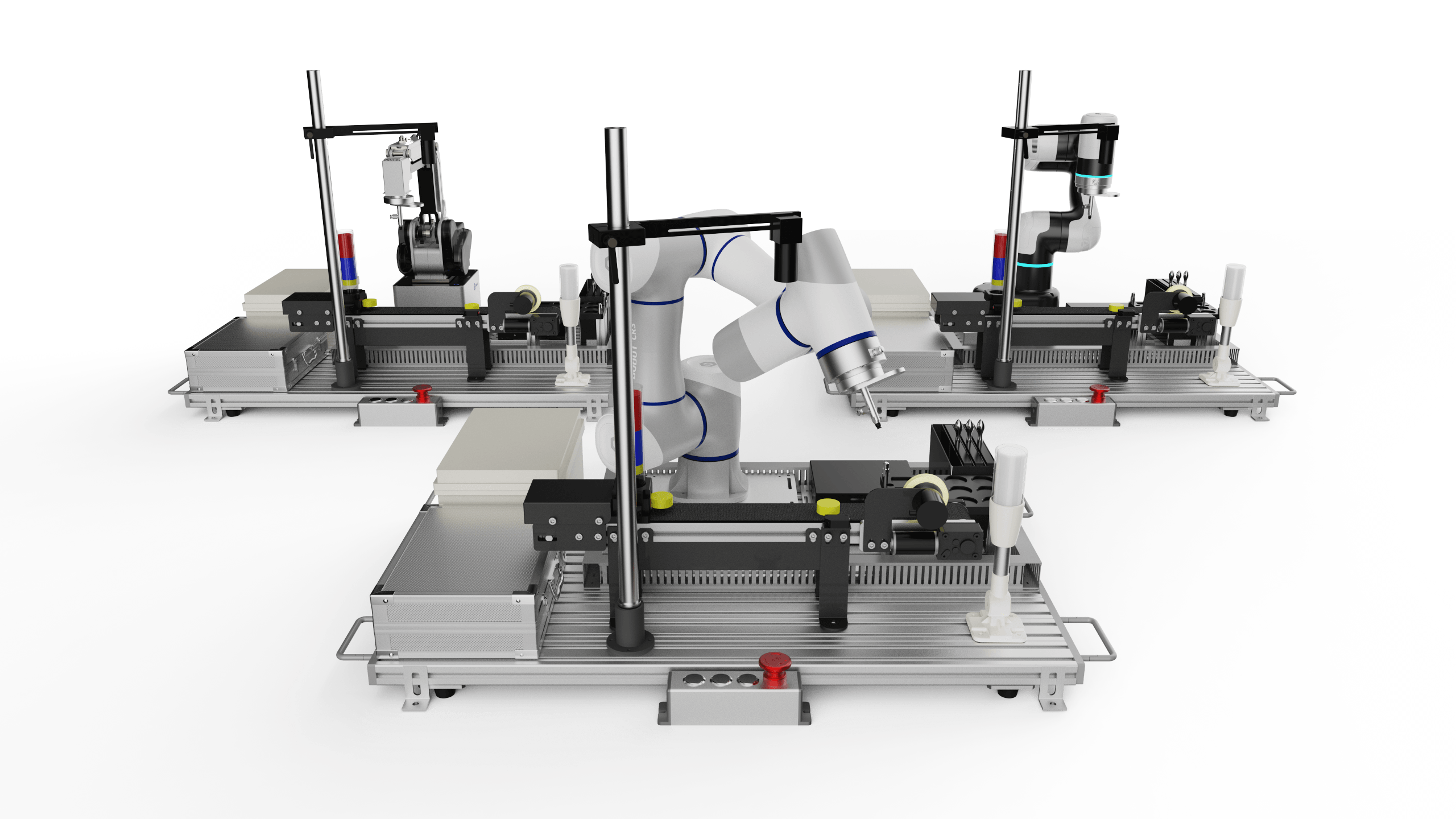

Injection machine robots play a significant role in modern manufacturing. These machines automate the injection molding process. They ensure high precision and efficiency. The process begins with the material being heated until it melts. Then, the molten material is injected into a mold. This happens very quickly, creating a solid part as it cools.

Once the mold is filled, the robot can remove the part when it's cooled. This step requires precise timing and coordination. Any delay can compromise the quality of the part. The robot functions by following programmed instructions. However, human oversight is crucial for adjustments. Mistakes can happen, leading to defects or wasted materials.

In terms of maintenance, the robots must be regularly checked for wear and tear. This is often overlooked, leading to unexpected breakdowns. Training staff to understand this machinery is also essential. Without proper knowledge, the risk of errors increases. Integrating these robots into production can drastically improve efficiency, yet it requires a balance of technology and human skill.

Applications and Benefits of Injection Machine Robots

Injection machine robots play a vital role in manufacturing. These machines automate the injection molding process. They are used in various industries. From automotive parts to medical devices, the applications are diverse.

One significant benefit is increased efficiency. These robots can operate continuously with minimal downtime. They also enhance precision. This results in lower waste and higher quality products. Additionally, they reduce labor costs, allowing companies to allocate resources better.

Tips for integrating these robots include assessing your production needs. It’s critical to evaluate the required speed and volume. Also, train your staff adequately to ensure a smooth transition. Monitor performance closely at first. This will help identify areas needing improvement. Fine-tuning is often necessary. Small adjustments can lead to significant gains in output and quality.

Future Trends in Injection Machine Robotics

The future trends in injection machine robotics promise to reshape manufacturing. These machines are becoming smarter. Integrating AI into robotic systems can enhance efficiency. Robots can analyze production data in real time. This capability reduces waste and improves the quality of products.

Collaboration between humans and robots is another exciting trend. Advanced sensors allow machines to work safely alongside workers. This cooperation can lead to a more flexible production environment. However, training is essential. Workers must adapt to new technologies. This transition may challenge traditional skill sets.

Sustainability also plays a significant role in future developments. Injection molding robots will increasingly focus on reducing energy consumption. Efforts to recycle materials will gain traction as well. Companies must rethink their processes. Balancing innovation and sustainability can be complex, but it is necessary for progress. As the industry evolves, reflection on these changes will be crucial.