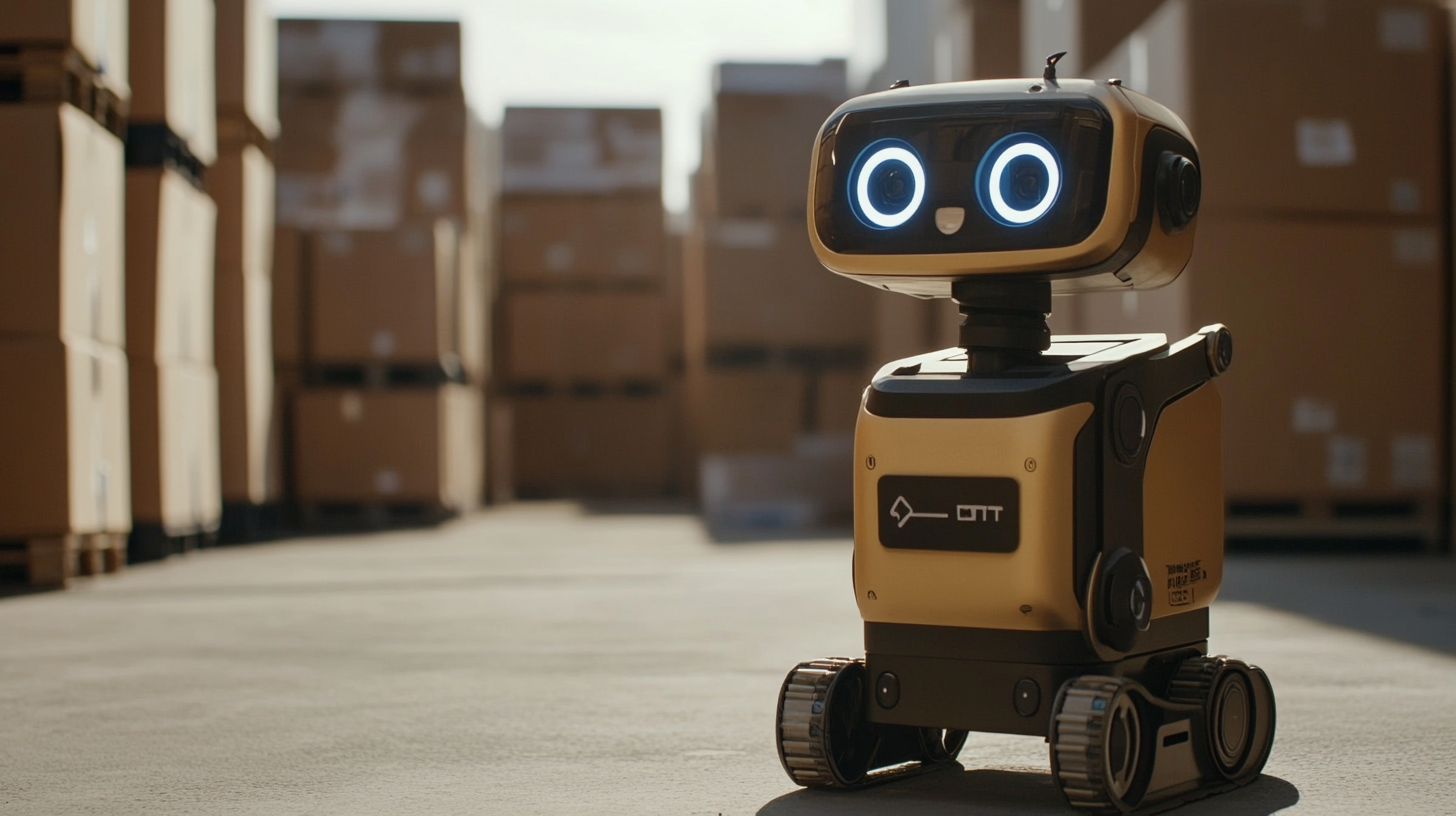

Exploring Innovative Options for Remote Control Robots in Your Supply Chain

As industries continuously evolve in the face of technological advancements, the integration of innovative solutions becomes imperative to enhance efficiency and drive productivity. Remote control robots have emerged as a transformative tool in various sectors, especially in supply chain management. These robots not only streamline operations but also offer unprecedented flexibility, allowing businesses to respond dynamically to challenges and demands. The exploration of remote control robots is vital for organizations seeking to harness automation and improve their logistics processes.

In this blog, we will delve into the various applications of remote control robots in the supply chain, examining how they are revolutionizing traditional practices. From warehouse automation to inventory management and last-mile delivery, the capabilities of remote control robots are rapidly expanding. We will highlight the benefits, potential challenges, and the future prospects of implementing these innovative options, positioning companies to thrive in an increasingly automated world. Join us as we uncover how embracing remote control robots can lead to a more agile and efficient supply chain ecosystem.

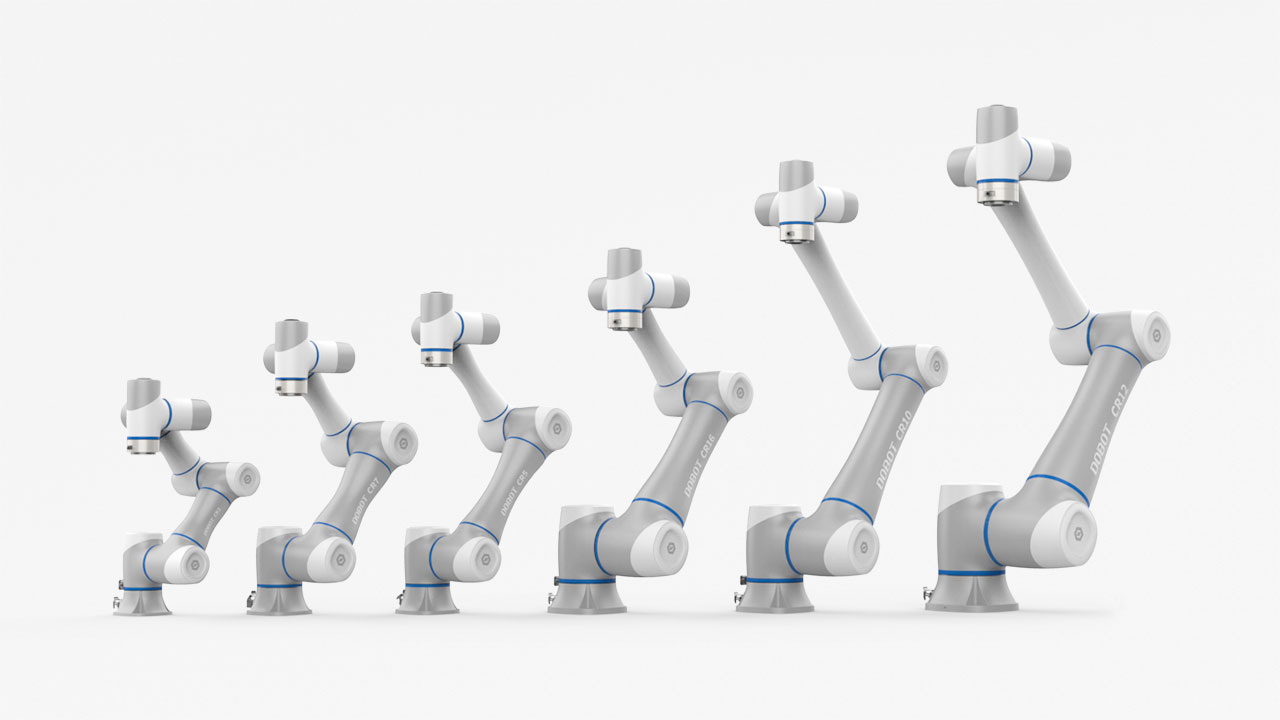

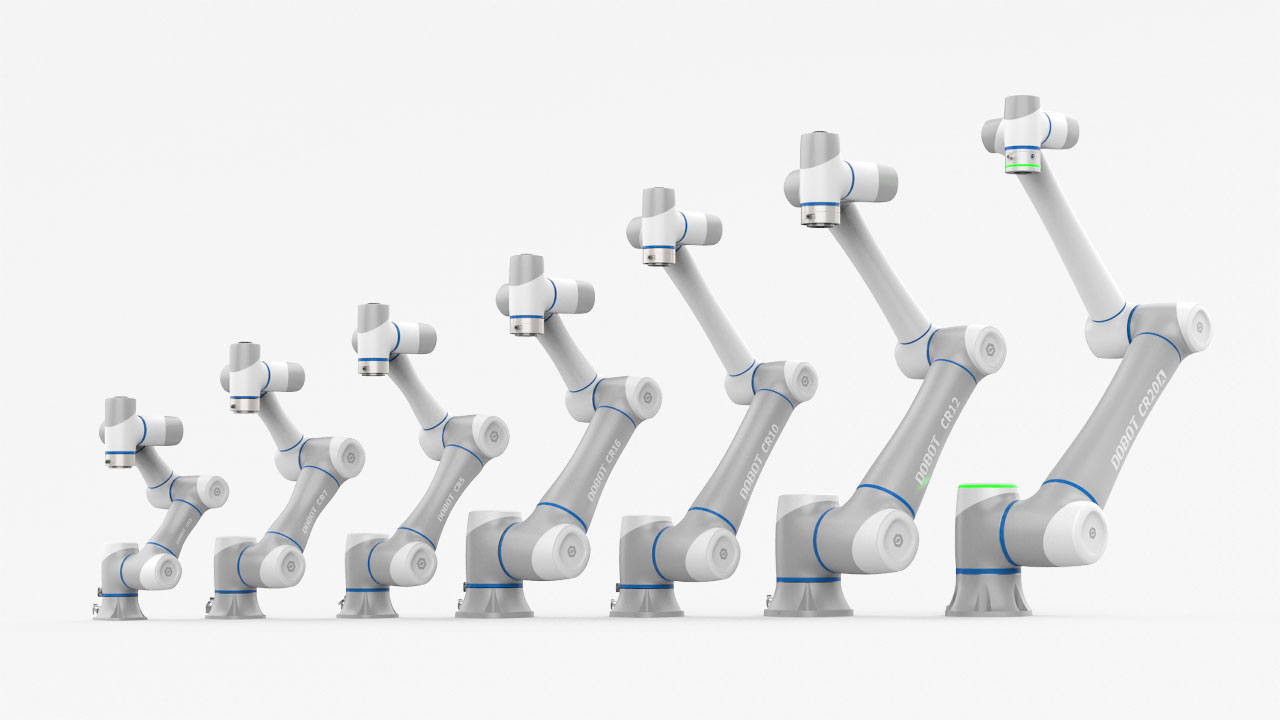

Innovative Robotic Solutions Transforming Supply Chain Efficiency

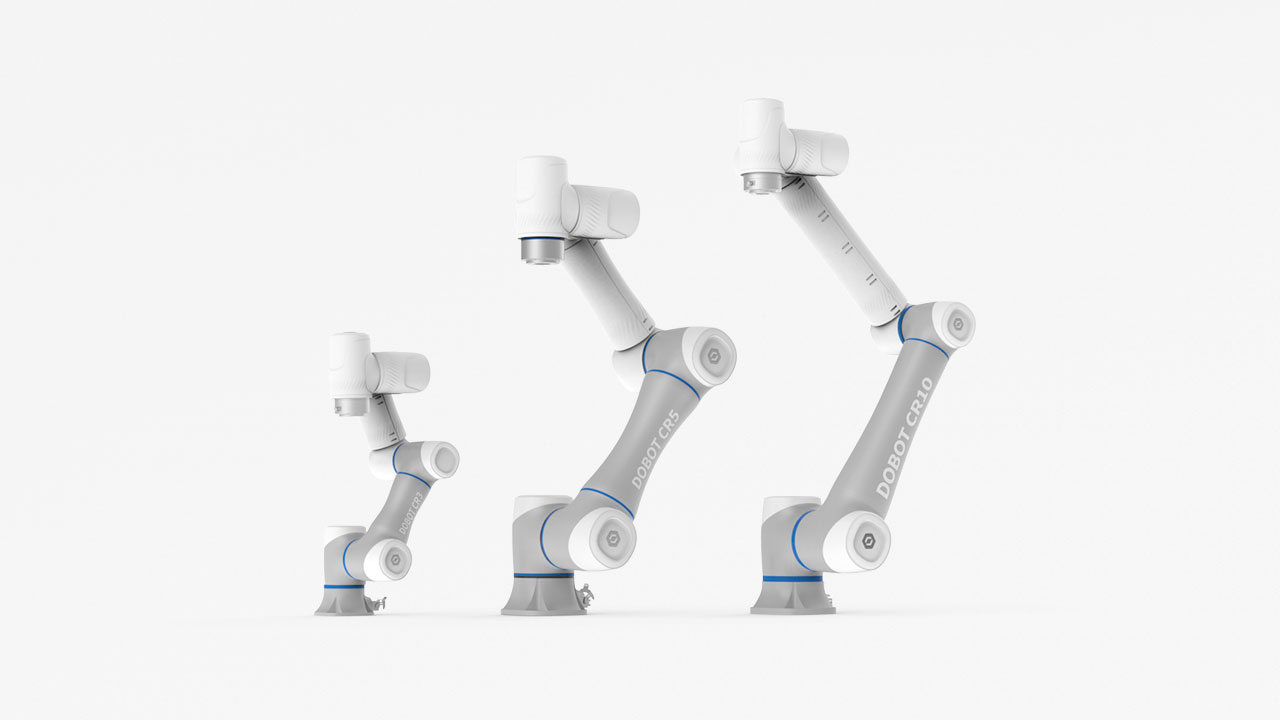

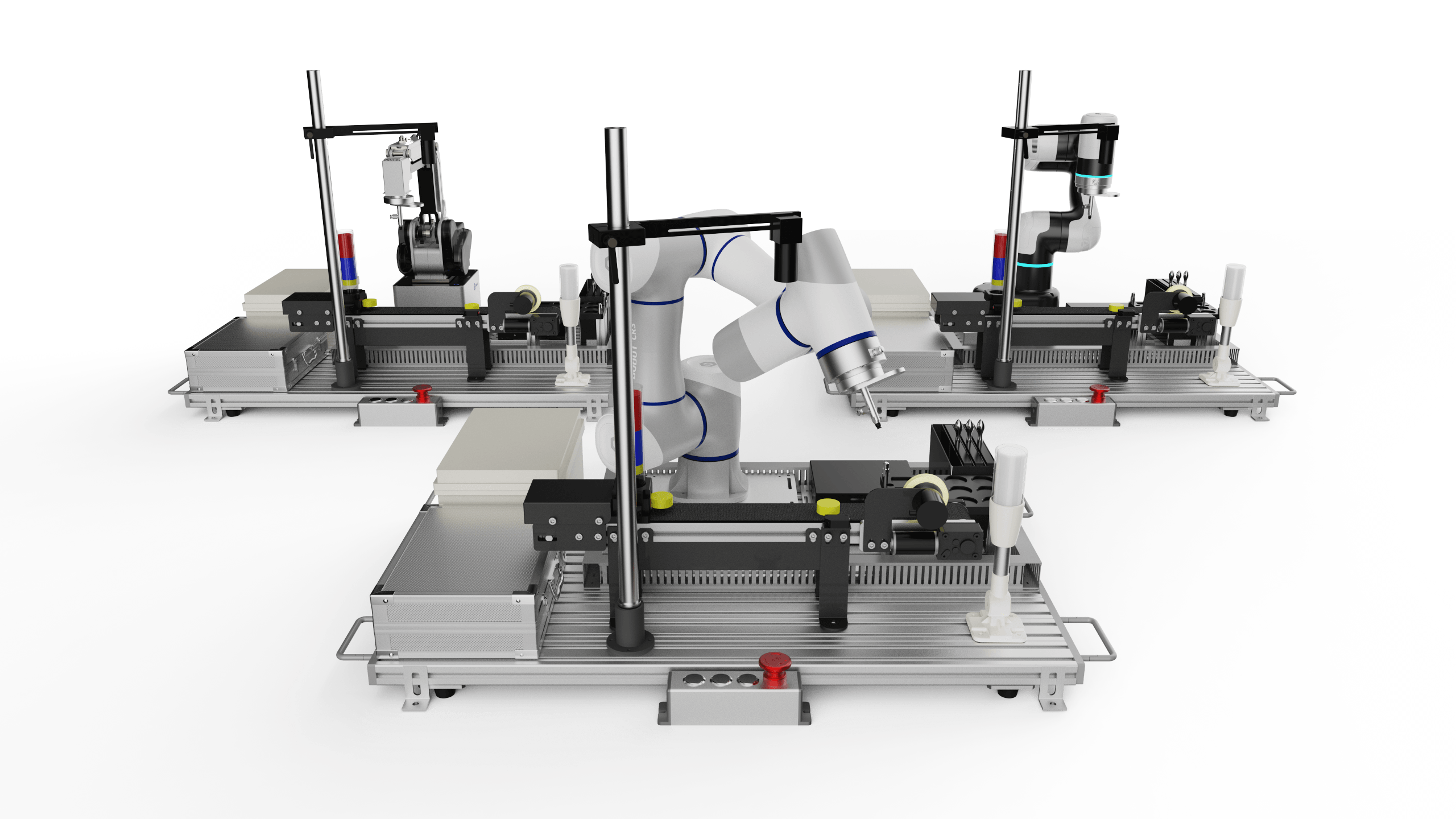

The logistics and supply chain sector is undergoing a transformative phase, driven by innovative robotic solutions that enhance efficiency and productivity. As companies seek to optimize their operations, the integration of remote control robots has emerged as a pivotal strategy. These advanced machines can navigate warehouses, manage inventory, and deliver goods, drastically reducing human error and speeding up processes.

One of the standout features of these robotic solutions is their ability to operate autonomously while still being remotely controlled when needed. This hybrid approach maximizes functionality, allowing for adaptability in dynamic environments. For instance, when unexpected challenges arise—such as product misplacements or sudden spikes in demand—operators can step in to guide robots precisely where they're needed. This level of control not only ensures smoother operations but also fosters a more responsive supply chain capable of meeting customer expectations.

Moreover, the data collected by these robots can be harnessed to refine logistics strategies further. By analyzing movement patterns and operational metrics, businesses can identify bottlenecks and streamline workflows. With insights gained from robotic systems, supply chains can evolve to be more efficient, ultimately leading to cost savings and enhanced service delivery. As we delve deeper into the realm of robotic automation, it becomes clear that these solutions are not merely an enhancement—they are revolutionizing how supply chains function in today's fast-paced economy.

Cost-Benefit Analysis of Implementing Remote Control Robots in Warehousing

The implementation of remote control robots in warehousing is gaining traction as companies seek to streamline operations and enhance efficiency. A recent report by the McKinsey Global Institute estimates that automation technologies, including remote control robotics, could yield a productivity increase of 20-25% in logistics and supply chain management by 2030. This presents a significant opportunity for businesses striving to reduce operational costs while improving service delivery.

Cost-benefit analysis reveals that the initial investment in remote control robots can be offset by substantial long-term savings. According to a study by the Institute of Supply Chain Management, organizations that deployed robotics technologies experienced an average reduction of labor costs by up to 30%. Furthermore, the accuracy of order picking improved by 99%, leading to a decrease in return rates. These benefits highlight how investing in remote control robots can translate into enhanced operational performance and better customer satisfaction.

Additionally, the scalability of robotic systems allows businesses to adapt to fluctuating demands without significant overhead costs. A report from the Robotics Industries Association indicates that the global market for logistics robots is expected to reach $37 billion by 2024, reflecting a compound annual growth rate of 24.5%. This growth underscores the profitability and practical advantages of adopting remote control robots, making them an essential component for modern warehousing operations.

Impact of Remote Control Robots on Labor Productivity and Safety Metrics

The introduction of remote control robots into supply chains has significantly impacted labor productivity and safety metrics across various industries. According to a report by McKinsey, companies that implemented robotics in their operations saw an average increase in productivity by up to 30%. This enhancement can be attributed to robots managing routine and repetitive tasks, allowing human workers to focus on more complex responsibilities that require critical thinking and creativity.

In addition to productivity gains, safety metrics have also seen marked improvement. A study by the National Institute for Occupational Safety and Health (NIOSH) found that workplaces that integrated remote control robots reported a 50% reduction in work-related injuries. By taking over dangerous tasks, such as lifting heavy items or navigating hazardous environments, these robots not only protect the workforce but also reduce the costs associated with medical claims and worker compensation.

Embracing remote control technology in supply chains fosters an environment where operational efficiency and worker safety are prioritized. This shift not only boosts overall morale among employees but also positions companies to remain competitive in an increasingly automated market. As the industry evolves, leveraging data-driven insights into labor productivity and safety will be essential for future innovations in supply chain management.

Case Studies of Successful Remote Control Robot Integration in Supply Chains

Remote control robots are becoming an integral part of modern supply chains, as evidenced by numerous successful implementations in various industries. A report by McKinsey indicates that automation can increase productivity in warehouses by up to 30%. One of the most prominent case studies comes from a major e-commerce retailer that integrated autonomous guided vehicles (AGVs) into their fulfillment centers. This implementation not only reduced the average order picking time by 25% but also cut labor costs by approximately 20%, showcasing the tangible benefits of incorporating remote-controlled solutions in high-paced environments.

In the automotive sector, a leading manufacturer adopted remote control robots to streamline its parts delivery process. By deploying these robots for intra-factory logistics, they achieved a 40% reduction in parts misplacement and a 30% faster turnaround time for assembly line operations. According to a report by Deloitte, automation in manufacturing can lead to a 10-30% improvement in efficiency, further supporting the case for remote control technology in supply chain management.

Additionally, a large pharmaceutical company successfully integrated remote control robots to handle the transportation of sensitive materials within their facilities. This approach not only ensured compliance with stringent safety standards but also led to a significant decrease in human handling errors, which, according to a PwC report, can cost companies up to $7 million annually in lost productivity and product waste. These examples illustrate the growing trend of adopting innovative remote control robot solutions, effectively transforming traditional supply chain practices.

Future Trends: AI and Automation in Enhancing Remote Control Robotics

The integration of artificial intelligence (AI) and automation into remote control robotics is revolutionizing supply chain management. According to a report by McKinsey, businesses that have adopted robotics and AI in their supply chains have seen productivity gains of up to 30%. As companies strive for efficiency, the future of remote control robots is becoming increasingly vital, especially in tasks that require precision and speed.

AI-driven robotics enhance decision-making processes by analyzing data in real-time. Research from Gartner indicates that 75% of organizations will use AI in their supply chains by 2025. This not only optimizes operational performance but also improves responsiveness to market demands. For instance, remote control robots equipped with AI can autonomously navigate warehouses, manage inventory, and even execute deliveries, minimizing human error and labor costs.

Moreover, the rise of autonomous robots in logistics aligns with the trends in workforce automation. The International Federation of Robotics projects a 20% annual growth in the adoption of collaborative robots—those that can work alongside humans. This indicates a shift in supply chain operations, where robots will increasingly take on roles that require high adaptability and efficiency, thus redefining how businesses operate in a digital economy. As AI technology continues to advance, the capabilities of remote control robotics will expand, paving the way for smarter, more efficient supply networks.