Top Strategies for Implementing Robotic Arm Technology to Boost Manufacturing Efficiency

The integration of Robotic Arm technology in manufacturing has emerged as a game-changer, significantly enhancing operational efficiency and productivity.

According to a report by the International Federation of Robotics, the global market for industrial robots is expected to reach $70 billion by 2025, with Robotic Arms accounting for a substantial portion of this growth.

This technology not only reduces labor costs but also improves precision and speed in production processes.

Furthermore, a study by McKinsey found that automation, including the use of Robotic Arms, could increase global productivity rates by up to 1.4% annually.

As businesses strive to remain competitive in an ever-evolving market, implementing Robotic Arm technology stands out as a critical strategy for streamlining operations, minimizing errors, and driving overall efficiency in manufacturing settings.

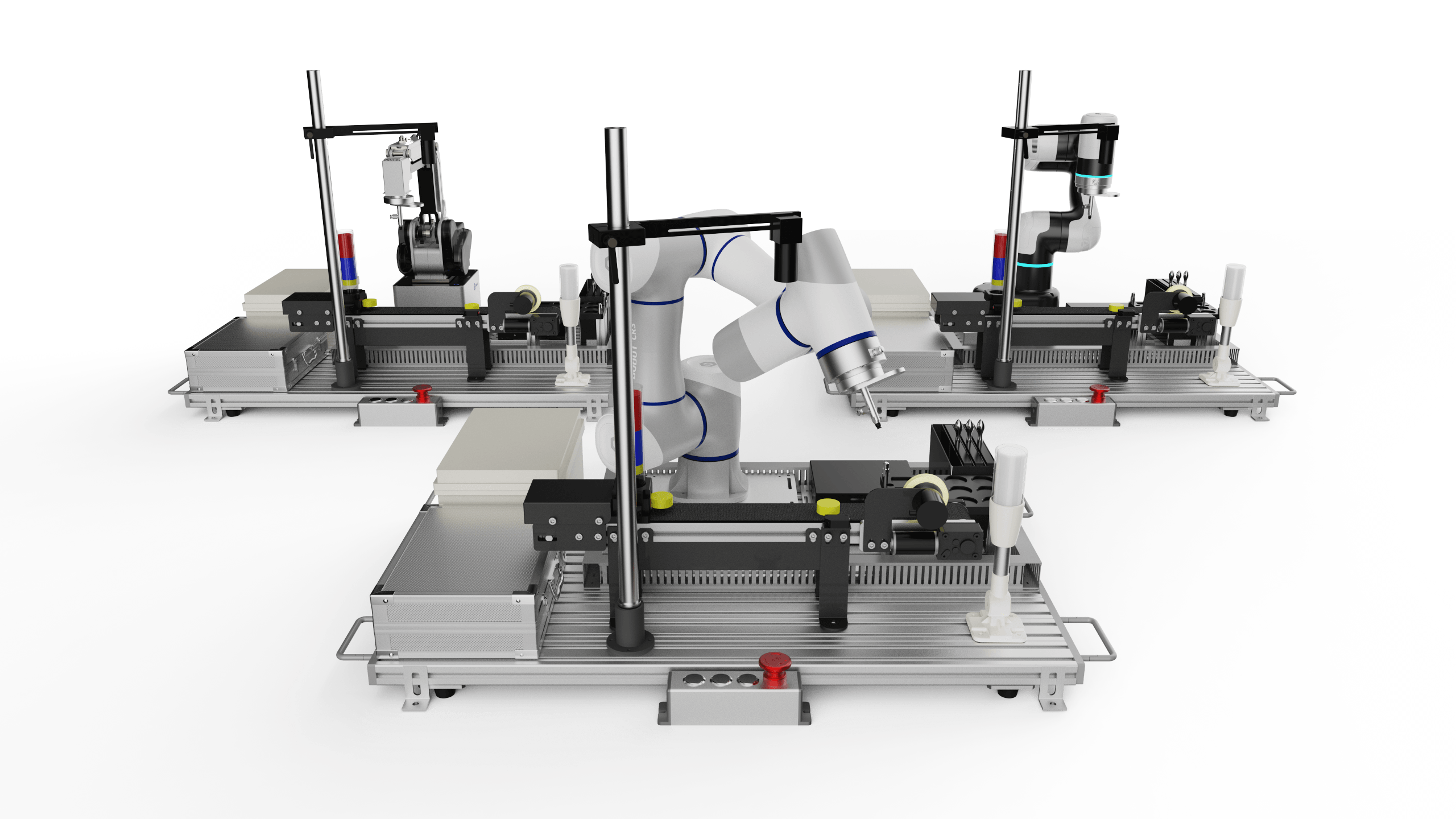

Identifying Key Manufacturing Processes for Robotic Arm Integration

The integration of robotic arm technology into manufacturing processes is revolutionizing productivity and efficiency. According to a report by the International Federation of Robotics, the global sales of industrial robots reached approximately 168,000 units in 2020, a clear indication of the industry's increasing shift towards automation. Key manufacturing processes that benefit significantly from robotic arms include assembly, welding, painting, and quality control. By employing robotic arms in these areas, manufacturers can enhance precision, reduce labor costs, and improve output speed.

One of the immediate advantages of robotic arm integration is in assembly lines, where repetitive tasks can be automated to achieve consistent quality. Statistics from McKinsey & Company highlight that automating just 45% of current tasks could boost productivity by up to 40%. Additionally, robotic arms operating in welding applications can minimize human error and ensure structural integrity in production, leading to enhanced safety and compliance with industry standards. As the technology continues to advance, companies are also exploring its application in complex tasks such as collaborative operations alongside human workers, further optimizing workflows and fostering a more agile manufacturing environment.

Top Strategies for Implementing Robotic Arm Technology to Boost Manufacturing Efficiency

Evaluating Cost-Benefit Analysis of Robotic Arm Implementation

Implementing robotic arm technology in manufacturing processes requires a thorough cost-benefit analysis to ensure a favorable return on investment. According to a report by the International Federation of Robotics (IFR), the global market for industrial robots is projected to reach $62 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 10%. This growth is largely driven by the increased demand for automation in various sectors, which can lead to significant cost savings. For instance, studies show that manufacturers adopting robotic arms can reduce labor costs by up to 30% and improve production speed by as much as 50%.

Additionally, assessing the long-term benefits of robotic arms includes evaluating improved product quality and consistency. A survey by McKinsey & Company revealed that companies utilizing automation technologies reported a 20% decrease in defects and an increase in overall operational efficiency. By accurately measuring the initial investment against these ongoing savings and performance improvements, manufacturers can make informed decisions about their automation strategy. Understanding these dynamics is crucial in leveraging robotic arm technology effectively, thus maximizing profitability in a competitive landscape.

Top Strategies for Implementing Robotic Arm Technology to Boost Manufacturing Efficiency - Evaluating Cost-Benefit Analysis of Robotic Arm Implementation

| Strategy |

Implementation Cost ($) |

Expected Annual Savings ($) |

Payback Period (Years) |

Efficiency Gain (%) |

| Automated Assembly |

250,000 |

100,000 |

2.5 |

20 |

| Material Handling |

150,000 |

60,000 |

2.5 |

15 |

| Welding Automation |

300,000 |

120,000 |

2.5 |

25 |

| Inspection Automation |

200,000 |

80,000 |

2.5 |

18 |

| Pick and Place Systems |

180,000 |

70,000 |

2.57 |

14 |

Training Workforce for Optimal Collaboration with Robotic Arms

As manufacturing industries increasingly adopt robotic arm technology, the focus shifts towards training the workforce to ensure optimal collaboration with these advanced machines. According to a report by the

International Federation of Robotics, the global stock of operational industrial robots reached 3 million units in 2021, a figure projected to grow by 10% annually. This surge highlights the pressing need for employees to develop skills tailored to working alongside automation, rather than viewing it as a replacement.

To effectively integrate robotic arms, companies should prioritize specialized training programs that cover both technical skills and collaborative techniques. For instance, incorporating hands-on workshops where employees learn to program and operate robotic arms fosters a deeper understanding and appreciation of the technology. Additionally, cross-functional training can enhance teamwork between humans and robots, allowing for a seamless workflow.

Tip: Invest in continuous learning platforms that provide up-to-date information on robotic technologies and their applications. Offering certifications in robotic programming and maintenance not only boosts employee morale but also equips the workforce with essential skills.

Moreover, regular assessments and feedback sessions can help identify training gaps. Engaging employees in the learning process allows them to voice concerns and share innovative ideas, fostering a culture of collaboration that is essential for maximizing the efficiency of robotic systems in manufacturing environments.

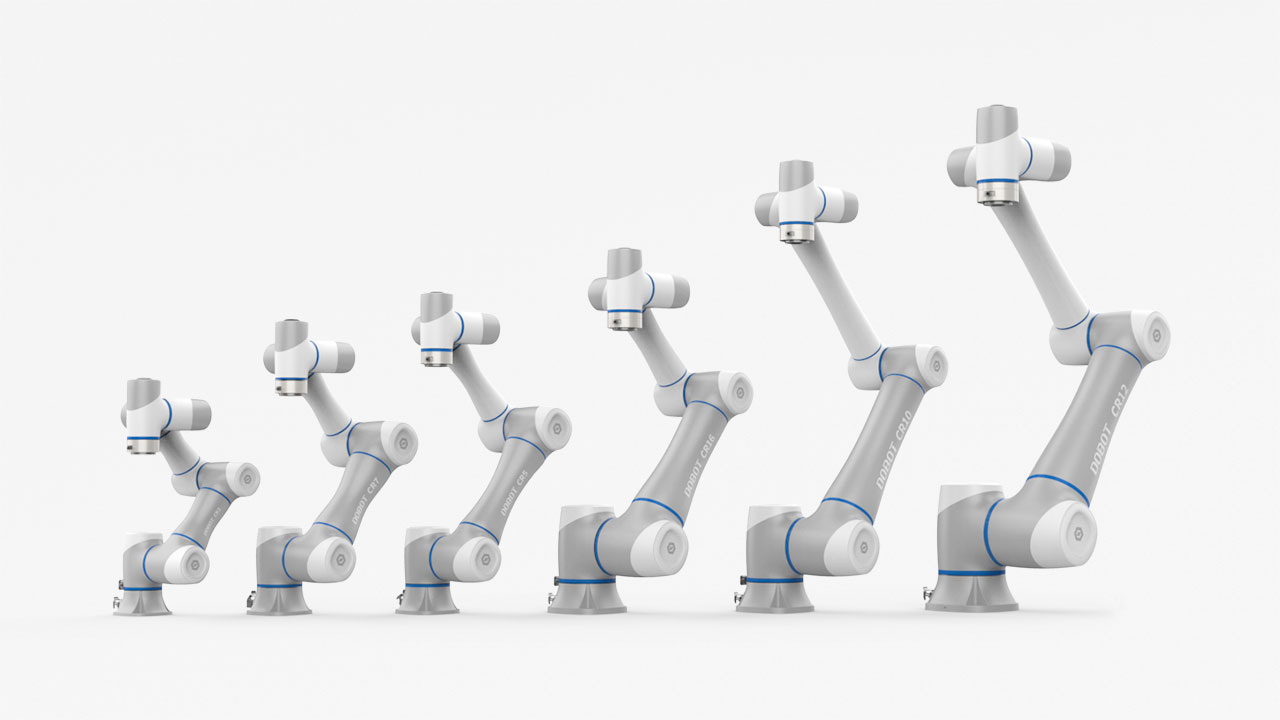

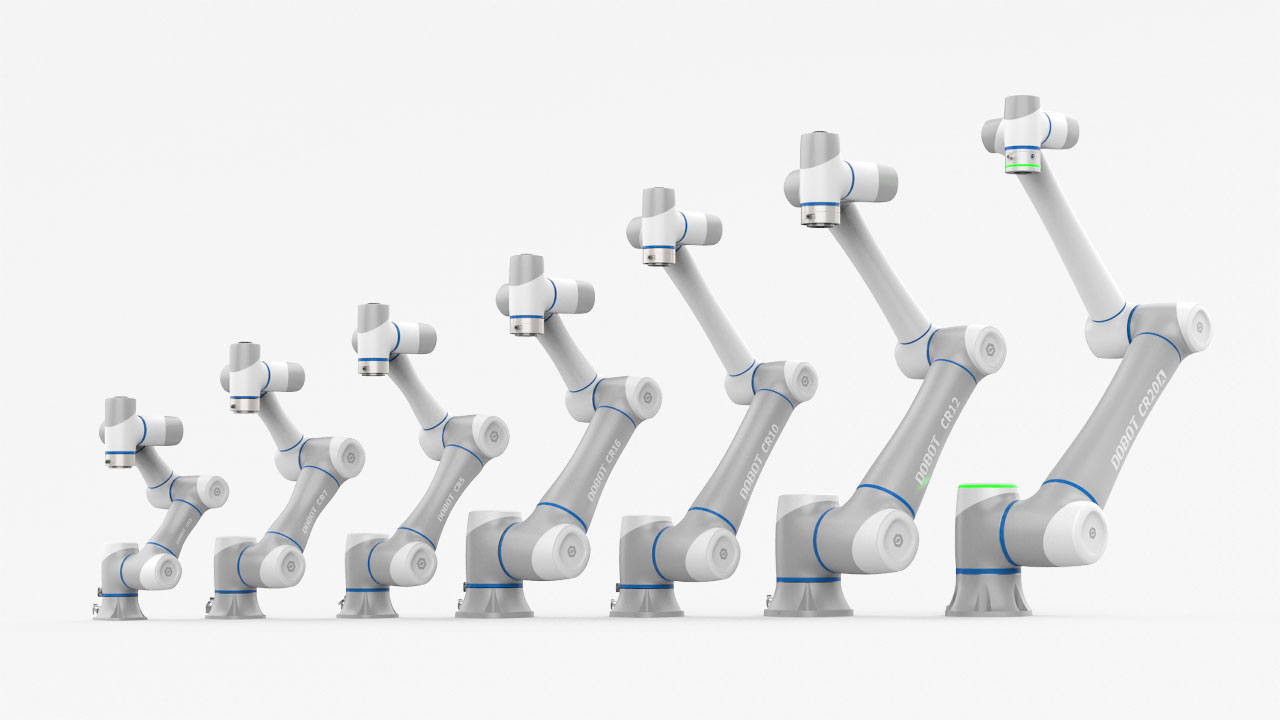

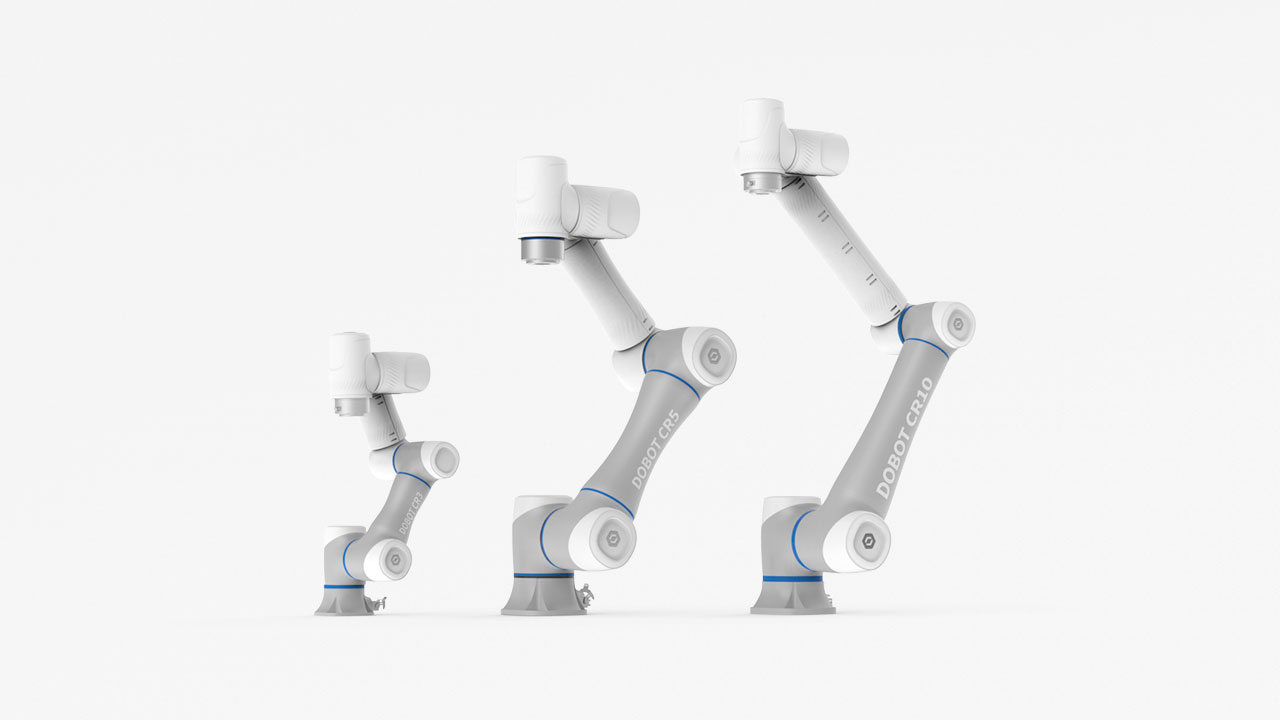

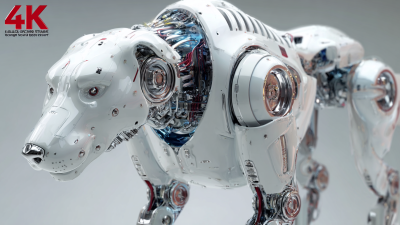

Selecting the Right Robotic Arm Technology for Specific Tasks

When selecting the right robotic arm technology for specific tasks in manufacturing, it's crucial to assess the unique needs of your operations. Different tasks require varying levels of precision, dexterity, and speed. Recent developments emphasize this necessity, with advancements like gaze-based intention estimation enhancing shared autonomy in pick-and-place tasks. This integration of human input ensures that robots can adapt to dynamic environments while performing complex operations seamlessly.

Tips for choosing the appropriate robotic arm include evaluating the workload and the types of objects to be handled. For instance, if the tasks involve handling multiple items simultaneously, consider using grippers designed for multi-object grasping. Additionally, advancements such as touch-sensitive capabilities in robotic arms allow for more delicate operations, which are particularly beneficial in industries like food processing where product quality is paramount.

Another critical aspect is the software integration that supports the robotic arm. Implementing systems that combine different platforms can optimize control and efficiency in operations. By leveraging technologies such as cloud-based control and AI enhancements, manufacturers can ensure their robotic arms are not only efficient but also adaptable to future needs.

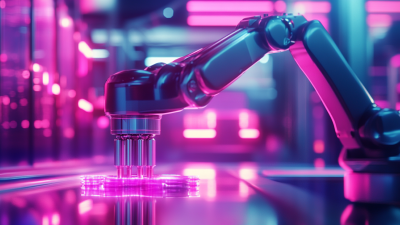

Continuous Monitoring and Improvement of Robotic Systems in Manufacturing

In the rapidly evolving world of manufacturing, continuous monitoring and improvement of robotic systems are crucial for maximizing efficiency. A recent report by McKinsey highlights that companies utilizing robotic arm technology can see efficiency increases of up to 30%. This potential uplift is only achievable when companies commit to real-time data analysis, ensuring that robotic systems are operating at peak performance. Continuous monitoring allows manufacturers to anticipate maintenance needs, reduce downtimes, and enhance overall productivity.

To effectively implement continuous monitoring, manufacturers should invest in advanced analytics tools that provide actionable insights. Regularly updating software and firmware can help maintain optimal performance, while predictive maintenance schedules based on usage data can significantly reduce unexpected failures.

Tip: Utilize IoT sensors to gather data on the robotic systems, allowing for real-time monitoring and quick decision-making.

Additionally, fostering a culture of continuous improvement within the workforce can drive successful implementation. By training employees to analyze robotic performance and providing them with the necessary tools, organizations can ensure that their robotic systems adapt to evolving production demands.

Tip: Encourage feedback from operators who work closely with robotic systems; their insights can be invaluable in pinpointing inefficiencies and potential areas for enhancement.