What is welded wire mesh and how is it used?

welded wire mesh is a versatile material widely used in construction and industrial applications. According to a report by Grand View Research, the global welded wire mesh market was valued at over $6 billion in 2022, showing promising growth. This material consists of wires that are welded together at intersections, providing strength and durability for various uses.

Expert John Smith, a leading figure in the wire mesh industry, states, "welded wire mesh revolutionizes structural integrity." This highlights its importance in creating stable frameworks for buildings and other projects. Welded wire mesh is commonly employed in concrete reinforcement, fencing, and even agricultural applications.

Despite its advantages, there are challenges. Quality control can vary among manufacturers. Poor-quality mesh may compromise project safety. Industry professionals must be vigilant about sourcing reliable materials. The welded wire mesh sector continues to evolve, indicating a need for ongoing improvement and innovation.

Definition and Composition of Welded Wire Mesh

Welded wire mesh is a versatile product used in various construction and industrial applications. Composed of intersecting steel wires, it is welded at each joint to create a strong and durable framework. The common materials used include carbon steel and stainless steel, delivering high tensile strength. According to industry reports, the global welded wire mesh market was valued at nearly $7 billion in 2022 and is projected to grow due to increasing construction demands.

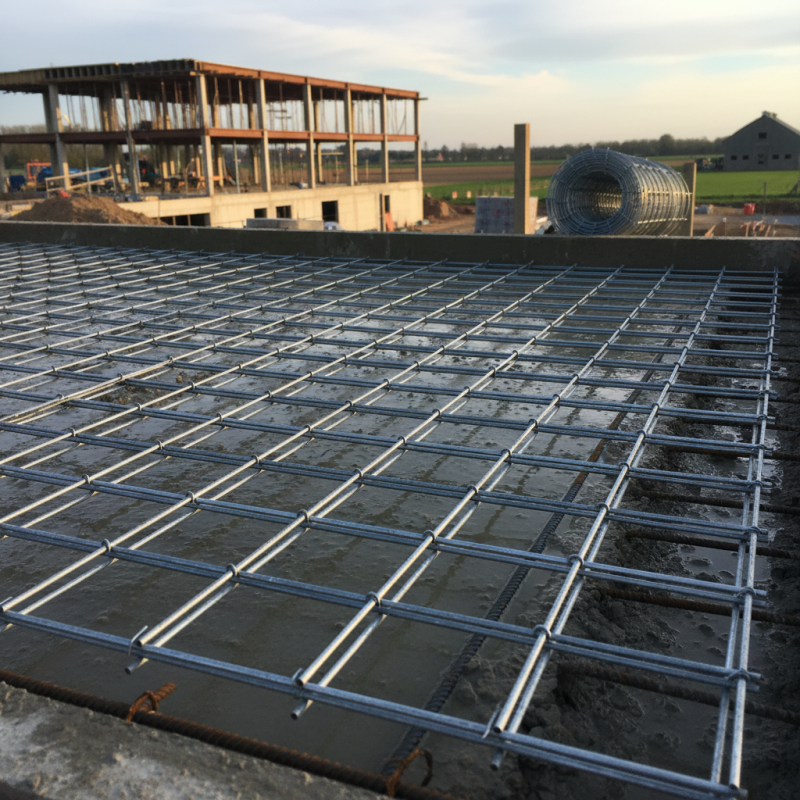

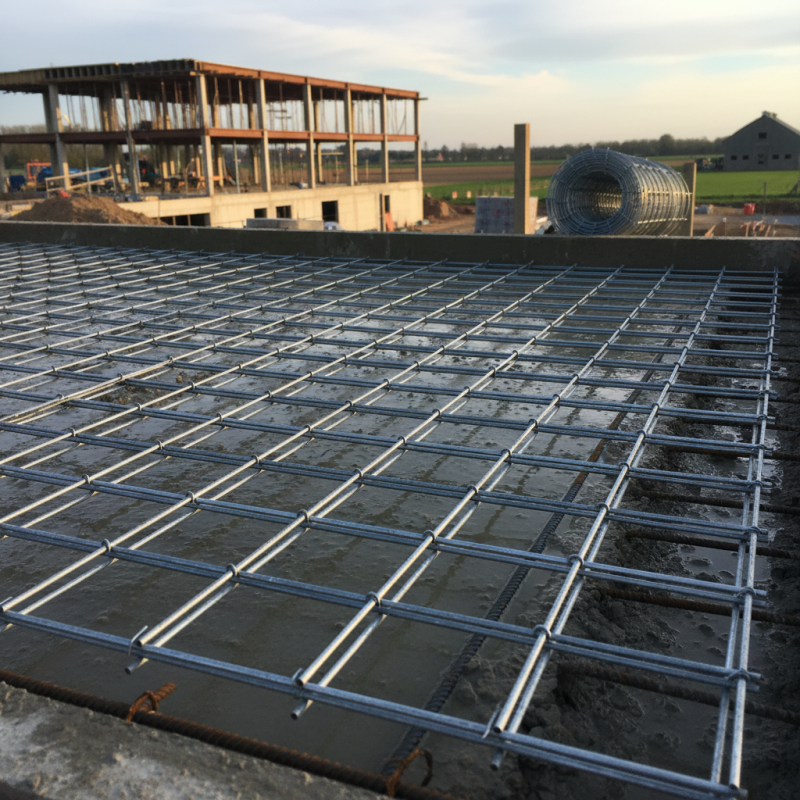

In practical uses, welded wire mesh provides support in concrete slabs, walls, and fences. It can also be adapted for agricultural purposes, helping in the construction of animal enclosures or garden trellises. This adaptability showcases its value across multiple sectors. One important aspect to consider is the wire's gauge, which affects the mesh strength and application. Thicker wires are often necessary for heavy-duty applications, while thinner wires may suffice for lighter uses.

Tips: When selecting welded wire mesh, assess both the spacing and gauge. This ensures it meets your specific needs. Additionally, consider local environmental factors, as corrosion resistance might be essential in certain areas.

Customizing welded wire mesh can sometimes lead to oversight. Adjustments to standard sizes or designs should be approached with caution. Rushing this process can lead to miscalculations and wasted resources. Always double-check measurements and consider consulting industry experts for your unique project specifications.

Common Applications of Welded Wire Mesh in Construction

Welded wire mesh is a versatile material widely used in the construction industry. Its strength and durability make it an excellent choice for various applications. For instance, it plays a significant role in reinforcing concrete structures. According to industry reports, welded wire mesh can improve the tensile strength of concrete by up to 30%. This enhancement is critical in building foundations and slabs, where structural integrity is paramount.

Another common application is in the production of fences. Welded wire mesh provides a robust barrier while allowing visibility and ventilation. This fencing is often used in agricultural settings, safeguarding crops from pests and livestock. In urban construction, it can define spaces in parks and commercial areas. However, some projects may overlook the importance of proper installation, which can lead to vulnerabilities.

Welded wire mesh is also utilized in road construction. It aids in stabilizing soils and minimizing erosion. It's noted that improper placement can diminish performance, leading to costly repairs. Despite its benefits, it’s essential to conduct thorough assessments before use. Quality control remains a challenge for many manufacturers, affecting reliability. Proper training and standards can mitigate these issues, ensuring its effective application in various construction domains.

Benefits of Using Welded Wire Mesh in Various Projects

Welded wire mesh is a versatile material widely used in various construction projects. Its strength and durability make it an ideal choice for reinforcing concrete, creating fences, and constructing animal enclosures. One of the primary benefits of using welded wire mesh is its ability to disperse stress evenly. This helps prevent cracks in concrete structures and enhances their overall longevity.

In landscaping, welded wire mesh can support plant growth by forming trellises or garden barriers. It allows for airflow and sunlight while keeping pests away. For agricultural projects, farmers can rely on welded wire mesh to build strong cages for crops or livestock. This sturdy material can withstand harsh weather, ensuring protection for essential resources.

**Tips:** When selecting welded wire mesh, consider the spacing between wires. Smaller openings provide better security but may limit visibility. Additionally, always check the gauge of the wire. A thicker gauge can offer increased strength, especially for heavy-duty applications. Remember, the right choice can make or break your project. Reflect on your specific needs and adjust your selections accordingly.

Types of Welded Wire Mesh and Their Specific Uses

Welded wire mesh is a versatile material used in various applications. It consists of wires that are welded together at intersections, creating a strong and durable grid. This structure is often used in construction, agriculture, and fencing. The mesh's strength is vital for many projects. According to industry reports, the global welded wire mesh market was valued at approximately $3 billion in 2021 and is projected to grow steadily.

There are several types of welded wire mesh, each with specific uses. Heavy-duty welded wire mesh is used in industrial settings. Its robustness supports concrete slabs, roadworks, and heavy machinery enclosures. In contrast, light gauge mesh is suitable for residential applications, such as garden fencing or animal enclosures. Standard mesh typically falls between these two categories, catering to various projects, for example, reinforcing walls or creating partitions.

Interestingly, the size of the mesh openings impacts its application. Smaller openings provide security, while larger gaps allow for visibility and ventilation. However, selecting the wrong type can lead to structural vulnerabilities. Project managers sometimes overlook this detail, which can be costly. The choice of material and gauge also affects durability and cost, complicating decision-making further.

Types of Welded Wire Mesh and Their Specific Uses

Installation and Maintenance of Welded Wire Mesh Products

Welded wire mesh is commonly used in construction and agriculture. Proper installation is crucial for ensuring durability and effectiveness. Begin by carefully measuring the area where the mesh will be placed. This step is often overlooked, leading to mistakes. Clear the site of debris and ensure the ground is level. A solid foundation is key to preventing future issues.

When installing welded wire mesh, proper tension is important. Ensure the mesh is taut to avoid sagging. Using the right tools can make this process easier, but it is easy to miss a step. Double-check the connections; they must be secure to maximize strength. After installation, regular maintenance is essential. Periodically inspect the mesh for rust or damage. Addressing these small issues early can prevent larger problems later on.

Cleaning the mesh is not always a priority, yet it matters. Dirt and debris can accumulate, leading to corrosion. A gentle scrub with soapy water can keep the surface clean. While maintenance might seem tedious, neglecting it can have consequences. Keep an eye on the structure’s integrity to ensure long-lasting use. Each detail matters in achieving the best outcome.